The capacitor production process includes cutting, winding, impregnation, assembly, aging, sealing, printing, casing, measurement, packaging, inspection and other processes.

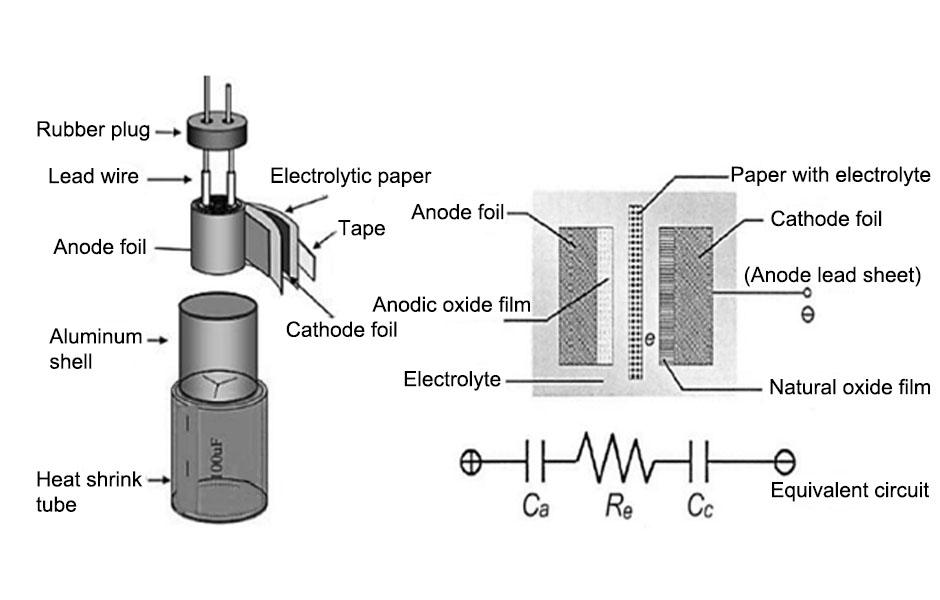

Among them, the cutting of aluminum foil is to cut a whole piece of aluminum foil into several small pieces to make it necessary for proper capacitor manufacturing; in the winding of electrolytic paper, the electrolyte in the capacitor is not directly poured into the capacitor, and it is liquid to soak the aluminum foil , But the electrolytic paper that has absorbed the electrolyte and the aluminum foil layer by layer.

The assembly of the capacitor is to assemble the aluminum shell on the surface of the capacitor and connect the outer leads at the same time. The capacitor has been fundamentally formed at this time; the crimping is a covered capacitor, and it is necessary to pass this step to cover the PVC film on the capacitor surface. Aluminum shell surface.