For some purchasers and engineers, when purchasing Snap-in aluminum electrolytic capacitors, they don’t know much about Snap-in aluminum electrolytic capacitors and don’t know how to judge the quality of Snap-in aluminum electrolytic capacitors. Our company summarizes the following customers often encountered A few points:

1 Voltage and capacity of Snap-in aluminum electrolytics capacitor;

Undoubtedly, the voltage and capacity are the most important of the capacitors purchased by the engineer; the voltage, the voltage of the product identification of the horn electrolytic capacitor generally refers to the rated voltage, that is, the working voltage. When the general engineer selects the horn electrolytic capacitor, Generally, a voltage level will be increased, such as: 400V circuit, engineers will generally choose 450v Snap-in aluminum electrolytic capacitor; this is for safety; another parameter of the voltage of Snap-in aluminum electrolytic capacitor is surge voltage, the so-called Surge voltage refers to the overvoltage that is often generated when the circuit is struck by lightning and when switching on or off inductive loads or large loads. If the surge voltage is too large, it may cause breakdown of the capacitor; therefore, engineers use Snap-in aluminum electrolysis In the selection of capacitors, you need to ask the surge voltage of the Snap-in aluminum electrolytic capacitor manufacturer; if the surge voltage of the circuit is 400v and the working voltage is 350v, you can choose a 400v Snap-in aluminum electrolytic capacitor or a 450v Snap-in capacitor; some companies In order to save costs, 350v horn capacitors are selected. The surge voltage of the later circuit is too long, which is likely to cause harm to the circuit and the capacitor.

Capacity. For Snap-in capacitors, the marking on the product is generally the rated capacity, the actual capacity, according to the international standard, the general error is -20%~+20%, generally speaking, the positive capacity error, the price will be more The internal control standard of the Snap-in capacitor capacity error of Shanghai BITCAP Technology Center is generally -8%~+8%.

2 The life of Snap-in aluminum electrolytic capacitors

Snap-in capacitors are also industrial consumables. In the actual purchase of horn capacitors, customers generally pay more attention to voltage and capacity, and less attention to life; in fact, the voltage and capacity of horn capacitors are guaranteed to be used, and the life is determined How long? When talking about the life of Snap-in capacitors, one cannot fail to mention temperature. The life of horn capacitors is closely related to temperature; according to the data provided by Shanghai BITCAP Technology Center, the current mainstream capacitor life is as follows:

Choose the type according to the actual needs of the machine. The European and American markets are generally 105℃ 3000h~6000h; 105℃ 12000h horn capacitors are generally used in places requiring ultra-long life electrolytic capacitors such as photovoltaic inverters;

Like some household appliances industry, where the temperature requirements are not high, it is recommended to use 85 degrees horn capacitors; there is a place to pay attention, in the use of horn type aluminum electrolytic capacitors, the working temperature should not exceed the rated temperature, generally speaking, the temperature exceeds Rated temperature, the life will be shortened sharply. When the rated temperature is 10 degrees, the life of the Snap-in capacitor will be reduced in general, and even the electrolyte will dry out. Therefore, when selecting the type, the engineer must choose the type according to the working environment of the capacitor. ; In the actual electrolytic capacitor selection process, there is still the principle of keeping margin. For example, an electrolytic capacitor with an actual operating temperature of 70 degrees, in the process of choosing a horn type electrolytic capacitor, people generally choose a horn capacitor of 105 degrees; In this way, there will be almost no problems with the capacitors. Even if the machine is in use, the warranty period has passed and problems occur, the electrolytic capacitors can still be used; this is one of the reasons why there are many second-hand capacitors on the market; Professional testing equipment is required; moreover, there is no problem in using second-hand capacitors at the beginning. Some internationally renowned brand Snap-in capacitors are indeed better than some domestic horn capacitor manufacturers after being refurbished;

3 Leakage current of Snap-in electrolytic capacitors

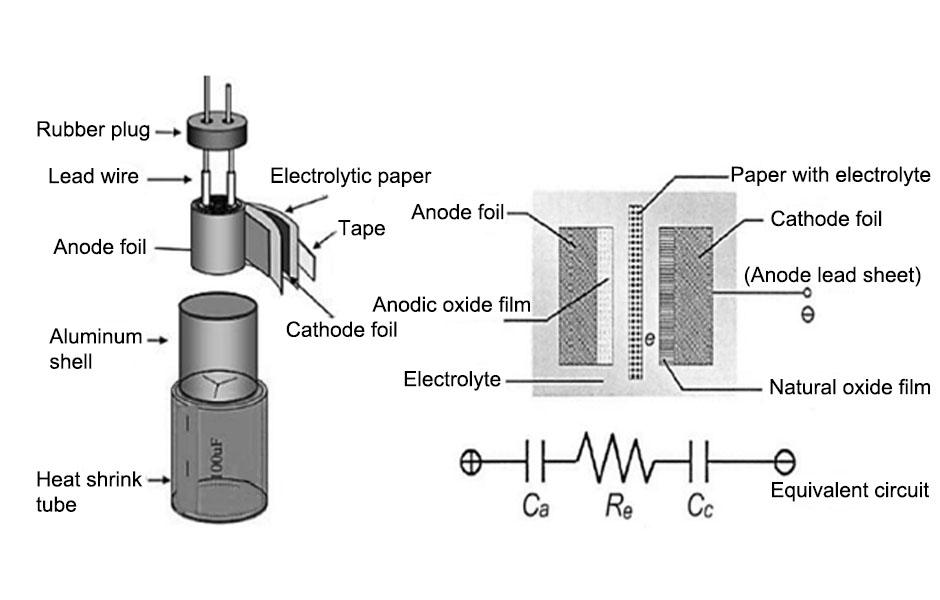

The source of the leakage current is that the oxide film of aluminum electrolytic capacitors, aluminum oxide, is formed by electrochemical methods. When a voltage is applied to a Snap-in capacitor, a flow of electrons is formed, which is the so-called leakage current; the magnitude of the leakage current It can be seen that the manufacturing process level and the quality of raw materials of the Snap-in capacitor manufacturers.

In the actual selection, the leakage current of the horn capacitor of the same specification is as small as possible; the reason is that if the leakage current is too large during the use of the horn capacitor, the life of the horn capacitor will be reduced, and the horn capacitor will fail early, thereby reducing The life of the machine;

4 Ripple current of Snap-in electrolytic capacitors

The ripple current of the horn capacitor refers to the effective value of the maximum allowable AC current at the specified frequency. The higher the rated ripple current of the horn capacitor produced by electrolytic capacitor manufacturers, the better the performance of the horn capacitor and the durability of the capacitor. The longer the performance, the reason is that each bullhorn electrolytic capacitor has a maximum rated ripple current value. Exceeding the rated current value will cause too much heat to be generated inside the capacitor and cause premature failure of the capacitor;