China is the world’s largest producer and exporter of capacitors, and is also a major consumer of capacitors. In the “12th Five-Year” development plan of the capacitor industry announced recently, it is clearly pointed out that the development of capacitors during the “12th Five-Year Plan” period is: new energy matching capacitors, power inverter capacitors, power inverter capacitors, automotive electronic capacitors. . It can be said that emerging industries such as energy conservation and environmental protection, information technology, new energy, new materials and new energy vehicles have brought new opportunities for capacitor development.

Domestic capacitor companies should be more forward-looking

At present, global capacitor production capacity is mainly concentrated in Japan, Taiwan and China. Compared with the former two, domestic capacitor production capacity is large, but most of them are low-end products. Therefore, Pan Da-nan, secretary general of the China Electronic Component Industry Association Capacitor Branch, pointed out: “Domestic capacitor companies should adapt to market changes, pay close attention to forward-looking industries, and continuously introduce products that meet the requirements of different complete machines to become bigger and stronger. Current capacitor manufacturers should Focus on the development of solar photovoltaic, wind power, tidal power, energy-saving lamps, electric vehicles, hybrid vehicles, automotive electronics, subways, high-speed rail, DC power transmission, triple play, HDTV, set-top boxes, mobile TV and other industries.”

The advantages of aluminum electrolytic capacitors are still huge

Capacitors account for about 40% of the total electronic components, while aluminum electrolytic capacitors account for 34% of the total capacitor production. Aluminum electrolytic capacitors, which have a wide range of voltage and capacitance, large power storage and low price, account for 44% of consumer electronics applications, mainly used in household appliances such as computers, color TVs, air conditioners, cameras, and CNC lathes.

With the continuous advancement of aluminum electrolytic capacitor technology and the continuous product structure, in recent years it has been widely used in automotive electronics, new energy, aerospace military and other fields, mainly used in the manufacture of energy-saving lamps, inverters, inverters, uninterruptible power supplies, etc. This will increase the market share of aluminum electrolytic capacitors in the entire capacitor market. High frequency, low impedance, long life, wide temperature, ultra small size, etc. will be the development direction of aluminum electrolytic capacitors.

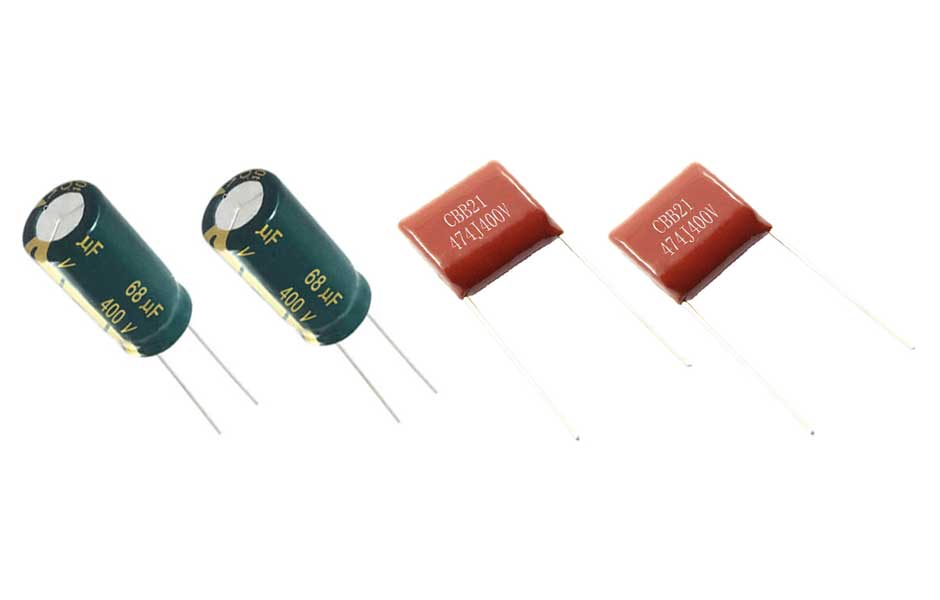

Film capacitors follow the trend

Compared with aluminum electrolytic capacitors, film capacitors have the advantages of good reliability, stable performance, and large capacity, and are more suitable for the harsh outdoor environment. Especially in the field of new energy vehicles, wind power, solar power, high-speed rail and light rail trains and high-voltage inverters, film capacitors have become the first choice due to their advantages in life, temperature and voltage.

It is understood that international wind power giant Vestas and other manufacturers have begun to use film capacitors, and Toyota New Energy Vehicle Prius II replaced aluminum electrolytic capacitors with film capacitors. In China, aluminum electrolytic capacitor giant Jianghai also invested 200 million yuan to build 10 high-voltage film capacitor production lines, forming an annual output of 1 million high-voltage large-capacity film capacitors, which is also preparing for future film capacitors for new energy vehicles.

As the world’s top five film capacitor manufacturers, Farah Electronics also expands the frequency conversion appliance and new energy market. The company’s AC film capacitors can be applied to many fields of new energy: hybrid vehicles, wind power, solar energy, etc. However, the shortcomings of large and high-priced film capacitors also have a great impact on market share. In order to meet the needs of new industries, high frequency, large capacity, high current, low impedance, high voltage, high dv / dt characteristics will be the development direction of film capacitors.

Film capacitor PK aluminum electrolytic capacitor, who will hold the ear in the future?

At present, the market capacity of aluminum electrolytic capacitors in the new energy market is still larger than that of film capacitors, but with excellent performance, the permeability of film capacitors is also constantly increasing. In the future, is the film capacitor who replaces the aluminum electrolytic capacitor, or does it distinguish the market according to the high pressure range? At the upcoming 78th China Electronics Show, sponsored by China Electronic Equipment Corporation and China Electronic Component Industry Association, China Electronics Business Magazine and China Electronic Component Industry Association Capacitor Branch hosted the “Capacitor Application and Selection Seminar” The application prospects and market development of these two capacitors in the green emerging industry will be discussed, and the selection and application design reference for engineers and procurement personnel will be provided to enhance the design and procurement capabilities of local engineers and procurement personnel in China.