Capacitors can be divided into four categories: aluminum electrolytic capacitors, tantalum electrolytic capacitors, ceramic capacitors, and film capacitors, among which aluminum electrolytic capacitors have significant advantages in terms of high unit volume CV value and high cost performance, occupying 30% of the capacitor market share.

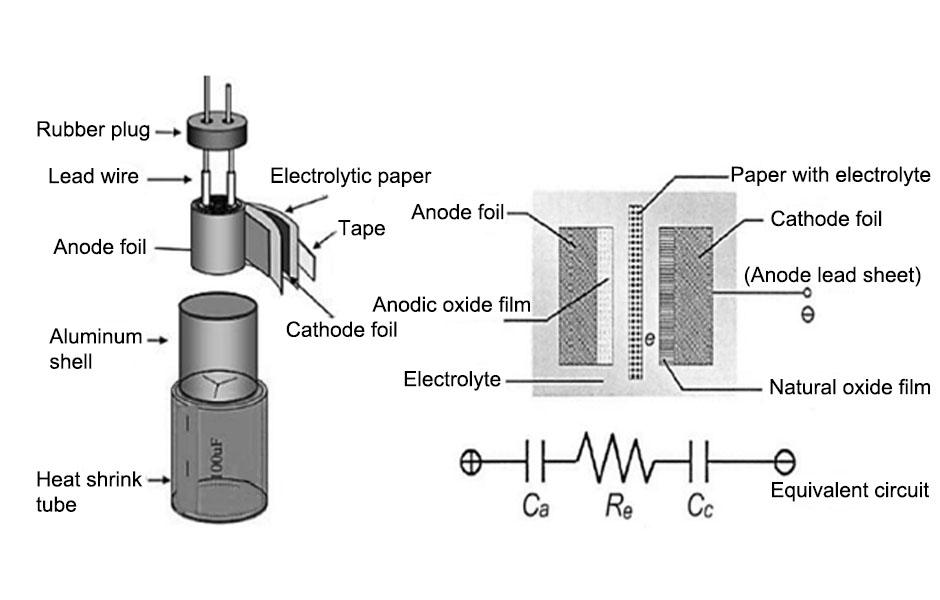

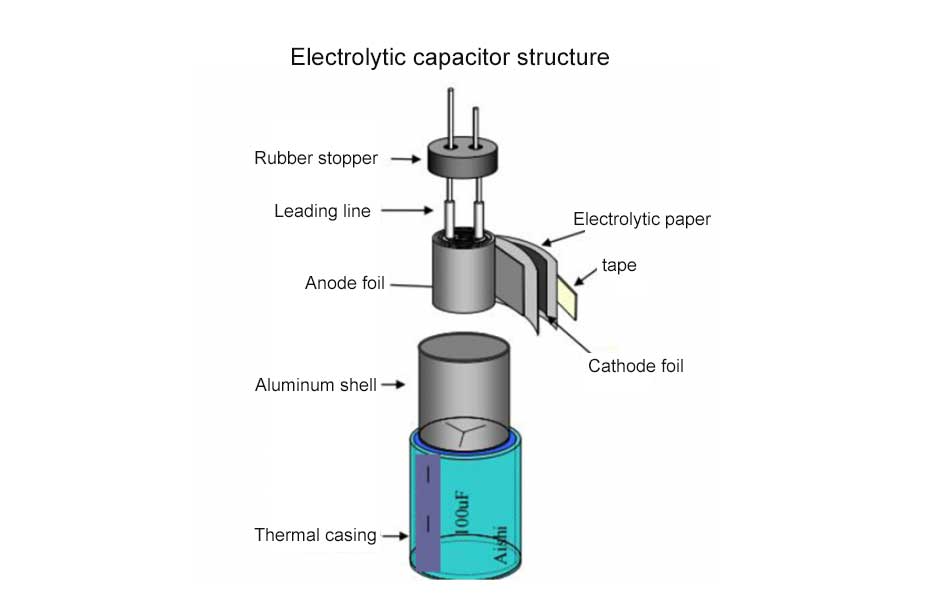

The aluminum electrolytic capacitor is a capacitor made by winding an anode foil, a cathode foil, an electrolytic paper in between, and dipping the working electrolyte, and then sealing it in an aluminum shell;

The aluminum electrolytic capacitor is a capacitor made by winding an anode foil, a cathode foil, an electrolytic paper in between, and dipping the working electrolyte, and then sealing it in an aluminum shell;

The main function of the aluminum electrolytic capacitor is as follows: AC and DC blocking, with functions of filtering, vibration elimination, resonance, bypass, coupling, and rapid charge and discharge. Compared with other capacitors, it has the characteristics of small size, large storage capacity, and low cost. ;

According to statistics from the Taiwan Industrial Research Institute, the global application of aluminum electrolytic capacitors is 45% of consumer electronics, 23% of industry, 13% of information, 7% of communications, 5% of automobiles, and 7% of other types. Consumer electrolytic capacitors are mainly used in consumer markets such as energy-saving lighting, televisions, monitors, computers, and air conditioners. Industrial aluminum electrolytic capacitors are mainly used in industrial and communications power supplies, professional inverters, numerical control and servo systems, wind power generation and automobiles. And other industrial fields.

According to statistics of the Electronic Components Industry Association, the global market size of aluminum electrolytic capacitors in 2017 is estimated to be 8.2 billion U.S. dollars, with a natural growth rate of 3-5%.

At present, according to Paumanok Publications Inc. statistics, Japan, Taiwan, South Korea, and China are the world’s major producers of aluminum electrolytic capacitors. Four of the world’s top five manufacturers of aluminum electrolytic capacitors are Japanese companies, which are: Nippon Chemi-con, Nichicon , Rubycon and Panasonic, Japanese manufacturers account for more than 60% of the global market share of aluminum electrolytic capacitors, China’s market share of more than 20%