1. The Importance of Equipment Installation Tracking

💐The DC converter station usually shoulders the important task of interconnecting large-scale power grids and transmitting electric energy with high power. The safe and stable operation of a single station often determines the safe and stable operation of the large power grid system, and the safe and stable operation of each equipment becomes The cornerstone of the safe and stable operation of the converter station. As the country with the largest number of DC converter stations and the richest operating experience in the world, China has accumulated a lot of experience in the operation and maintenance of converter stations. Years of operating experience of DC converter stations show that the operation and maintenance personnel can effectively reduce the number of defects and hidden dangers after the equipment is put into operation to a considerable extent, and ensure the safety of the equipment for a long period of time. Stable capacitor device operation.

🎄The equipment owned by the ordinary AC substation is all included in the DC converter station, and the converter station also has the equipment that the AC substation does not have (converter valve, DC field equipment, water cooling system equipment, AC and DC filters and shunt capacitors). equipment, etc.), the technical content and complexity of the equipment structure of these equipment are much more complicated than those of ordinary AC substation equipment, which determines the complexity of the equipment installation, construction, and debugging processes. The tracking of the equipment installation process can directly integrate various experiences accumulated in the daily operation and maintenance process of the converter station into the equipment installation process, and eliminate the incorrect, unreasonable and non-standard installation methods and installation problems found on site in the bud. , to ensure the health level of the equipment after it is put into operation.

🌵The complexity and importance of DC equipment also determine that it cannot only focus on result acceptance, surface acceptance, and functional acceptance like ordinary substations. The operation and maintenance personnel of the DC converter station should follow up and accept the whole process of the equipment civil construction foundation, the equipment factory test equipment, unpacking, installation, on-site handover test, and commissioning, and especially strengthen the tracking and acceptance of concealed projects, so as to maximize the Such hidden dangers are eliminated in the infrastructure stage.

🌳The construction of the DC converter station is heavy and time-consuming, and the operation and maintenance personnel of the converter station are particularly required to strengthen the tracking of equipment installation, and the equipment operation and maintenance personnel are more likely to find problems and solve problems with the sense of responsibility of the owner, which ensures the quality of equipment installation. At the same time, the installation and tracking of DC converter station equipment can in turn cultivate DC converter station operation and maintenance professionals, so that the tracking personnel can better understand and master all kinds of equipment knowledge.

🌴The tracking of the equipment installation process is very important for the operation and maintenance of the DC converter station and the training of talents. At present, the State Grid Corporation of China’s system converter station has initially formed a relatively complete method system for equipment installation tracking. It guides operation and maintenance personnel to learn equipment installation by compiling operational documents and summaries such as tracking, acceptance work instructions, and equipment infrastructure installation and commissioning daily reports.

2. Installation and tracking content of AC and DC filters and shunt capacitor device

☘️The installation and tracking content of AC and DC filters and shunt capacitor device mainly includes five stages (of course, this is also the stage process of most equipment tracking restrictions): 1. The tracking of civil infrastructure; 2. The tracking after the equipment arrives at the site; 3. The equipment installation process Trace limit: ④The limit of equipment debugging and test; ⑤The acceptance of equipment after construction is completed. The following is a detailed description of the installation and tracking content and precautions of AC and DC filters and shunt capacitor devices from these five aspects.

2.1 Tracking of civil infrastructure construction

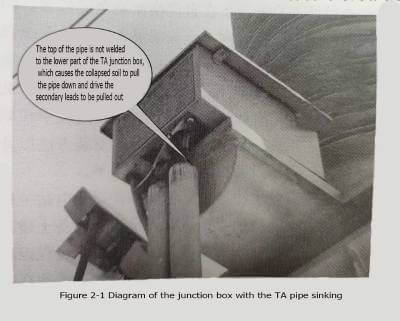

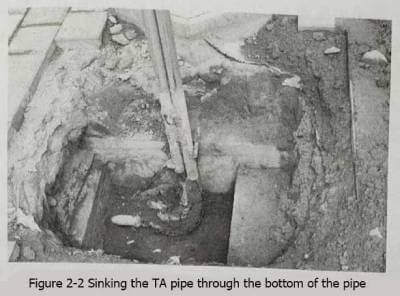

🌿In the eyes of many substation and converter station operation and maintenance personnel, the tracking of civil engineering construction is usually regarded as a “chicken rib” project, and the tracking and acceptance are not paid attention to, which leads to many problems, such as: failure of foundation treatment and operation 1~2 After the year, the ground around the equipment foundation collapsed and subsided, which seriously threatened the safe and stable operation of the equipment. A domestic converter station once had the collapse of the ground around the AC filter high-voltage TA (current transformer), which caused the TA secondary cable to pass through the pipe and the TA junction box. The danger of serious detachment failure, as shown in Figure 2-1 and Figure 2-2, makes the operator have to apply to stop the group of filters for disposal, so as to prevent the serious consequences of the bus differential action caused by the failure of the filter TA circuit This situation is especially aimed at the foundation with collapsible loess structure in parts of the northwest. If it is not handled properly in the construction stage or after its maintenance, it will easily lead to the occurrence of this problem.

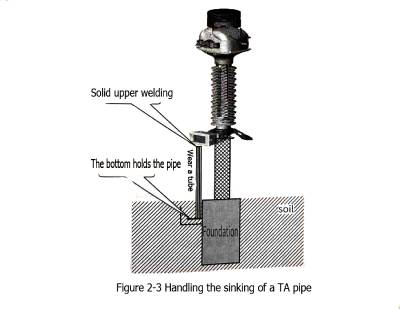

🍀Of course, to solve this problem, on the one hand, from the perspective of treating symptoms, that is, the foundation treatment in the infrastructure construction stage requires the construction unit to work hard to keep the foundation soil stable (3/7 of the lime soil can be rammed to a certain thickness or the opinions of the relevant designers can be obtained. ) to prevent collapse and subsidence; on the other hand, the method shown in Figure 2-3 can be used on the upper and lower parts of the through-pipe, and the upper through-pipe and the bottom of the TA are welded at the fixed position to prevent the through-pipe from sinking.

🌱The lower part adopts a plate with an “L”-shaped section; you hold it through a tube to prevent it from sinking. Under normal circumstances, in the infrastructure stage, the TA manufacturer or construction party is required to weld the upper through-pipe and the fixed position of the TA bottom. If this method is adopted, the through-pipe is still pulled down, and the bottom can only be further supported to prevent sinking.

🌟In addition, if the surrounding of the equipment foundation is not properly handled, the equipment may be tilted, and the insulators will be broken due to lateral tension, resulting in equipment accidents.

✨Civil infrastructure tracking is often the first step in equipment site tracking. According to experience, it mainly focuses on tracking from the following aspects.

(1) Tracking of civil works around the equipment foundation. Whether the backfill around the concrete foundation of the equipment is in accordance with the civil construction

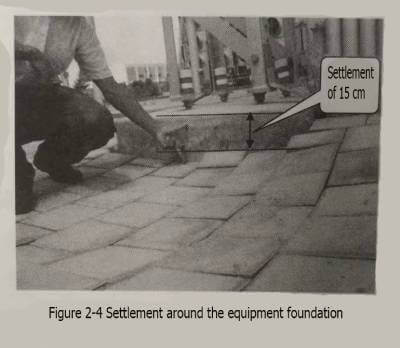

⚡️The process required by the engineering drawings is carried out, eg. The rammed thickness of limestone (lime and clay are mixed in a certain proportion) layer, the thickness of the gravel layer, the thickness of the concrete surface, whether the ground has horizontal or inclination requirements, etc. All these require our tracking personnel to be familiar with the drawings first, and only then can they go to the site to have a purpose. to track. In this way, we can not only learn something, but also become familiar with the scene. As shown in Figure 2-4, the backfill around the concrete foundation is not up to standard, resulting in the settlement of the ground around the equipment foundation in Figure 2-4, threatening the safe and stable operation of the equipment.

❄️(2)Tracking of equipment foundation civil works. The so-called equipment foundation usually refers to the concrete structure on which the equipment body is installed. The concrete structure is embedded to a certain depth below the ground to ensure that the equipment above the ground is firm and stable. This part of the tracking should be checked whether the construction party conducts the construction of the structure according to the requirements of the drawings. , Whether the shape of the structure, the depth of construction, and the maintenance of concrete after construction (especially in the cold environment in winter) meet the requirements, otherwise it will seriously affect the quality of concrete.

🍏(3)Grounding grid construction. In the construction of grounding grid, special attention should be paid to the process acceptance. After the construction unit completes the laying and welding of the grounding grid, due to the next step of construction, the earthwork should be backfilled soon. Before the earthwork backfill, the general construction party The supervision and operation unit tracking personnel will be notified to take photos for acceptance. This acceptance process is usually called hidden project acceptance in engineering. Since the grounding grid will be used for safety grounding, protection grounding, signal grounding, etc. of various equipment in the future, and also as a leakage channel for various old currents, it also plays an important role in the operation of the entire substation. In the acceptance of grounding grid, attention should be paid to whether the material, shape, etc. used in the grounding grid meet the requirements of the regulations (design drawings), and whether the welding process meets the welding quality requirements. After the photo tracers take pictures and keep them, they must be archived and sorted out in time, and they will be archived as the basic data for the construction of substations in the future.

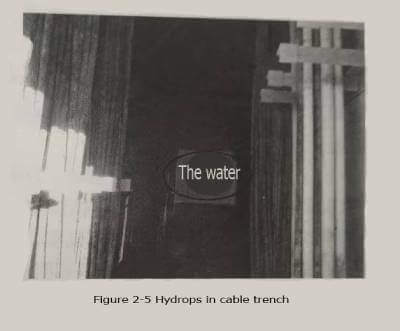

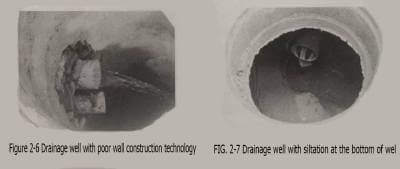

🍎(4) Construction of cable channel and drainage facilities of filter yard. On-site tracking personnel track whether the cable trench construction meets the design requirements. In addition, attention should be paid to whether the trench firewall layout meets the standard requirements (familiar with the standards before tracking), and whether there are drainage holes in the cable trench, such as poor drainage of the cable trench. , it is very likely to cause a large amount of accumulated water in the ditch that cannot be discharged after rain as shown in Figure 2-5, which can seriously lead to cable damage, DC grounding, and protection malfunction. The filter field is usually located on a large area of hardened concrete ground. Attention should be paid to tracking whether the drainage facilities on the ground are constructed according to the requirements, and whether the concrete ground has inclination requirements. If it encounters rainy weather during the construction process, this is the best opportunity to check whether the drainage of the large-scale concrete construction ground is smooth, and whether the drainage wells and rainwater wells function normally. Inspect the ground, drainage wells and rainwater wells, and urge the construction unit to deal with serious problems in a timely manner. In the inspection of underground drainage wells, attention should be paid to whether the well walls and underground parts are in good condition, otherwise the long running time may cause the well wall to collapse. Soil entering into the well. The phenomenon of silting the drainage pipes (usually the construction quality of this part is poor, and it is not easy to attract the attention of all parties), as shown in Figure 2-6 and Figure 2-7.

🍐(5)The method to solve the problem in the tracking process. In the process of civil construction tracking, the construction party does not construct according to the design drawings, the construction does not meet the construction standards (standards usually refer to national industry standards, design specifications, enterprise standards with certain effect, administrative documents, etc.), or somewhere in the project If there are serious hidden dangers and defects, the tracking personnel can take pictures on the spot, issue a project contact sheet, submit it to the supervisor, and the construction party or design institute will carry out rectification within a time limit (the method of issuing a project contact sheet is also applicable to various on-site tracking occasions) , and these contact lists with on-site infrastructure units and equipment manufacturers are archived as engineering basic data.

2.2 Tracking after filter equipment arrives

🍊After the filter equipment arrives at the site, before unpacking, the supervisor and the operation and maintenance unit will generally be notified to be present for witnessing, and there will usually be personnel from the equipment manufacturer present. The following points should be noted at this time:

🍉(1)Check whether the external packaging of various types of filter equipment (capacitors, resistors, reactors, mutual inductors, and arresters) is damaged. Pay attention to whether the damaged external packaging equipment is in good condition, and check carefully. Minor damages due to long-term operation hidden dangers (constructors or manufacturers do not consider them to be damages) should be boldly proposed and photographed for retention.

🍇(2)Pay attention to the collection of equipment certificate, factory manual, test report, etc., or collected by the construction unit, and handed over as data in the future, but the tracking personnel should keep a record of the data to ensure the integrity of future data transfer.

🍓(3)Pay attention to the collection and arrangement of basic equipment information, and prepare for the compilation of substation operation procedures, maintenance test procedures and equipment ledger. The data collected by photographing or recording mainly include: ① capacitors, resistors, reactors, arresters, transformer nameplates, these should correspond to the equipment (capacitors, reactors, resistors, transformers, arresters, etc. in a group There are usually many kinds in the filter); ②The schematic diagram of the grouping of the capacitor tower: Usually, before the capacitor leaves the factory, the bridge arm of the capacitor tower has been trimmed according to the measured value of its capacitance, so the position of each capacitor on the tower has been fixed, and the construction party only needs to The installation and wiring can be carried out according to the grouping diagram. While paying attention to collecting the above equipment parameters, it is specially reminded that you should also pay attention to collecting the insulator information in the filter field, mainly including the model and design creepage distance, etc., for the future work related to equipment pollution flashover. data accumulation

🍒(4)After the capacitor equipment arrives, in order to ensure product quality, a batch sampling test should generally be carried out, at least one capacitor unit of each type in each batch should be carried out. A batch refers to all products that are filled with oil at the same time. When the number of certain capacitors in a batch of products exceeds 50, the sampling rate should not be less than 2%. If any capacitor fails any test, the construction and construction unit has the right to reject all capacitors in the batch. The operation and maintenance personnel should supervise the construction unit to carry out the work during this process to prevent the capacitors with batch problems from being damaged. Tower, long-term hidden danger to equipment operation.

2.3 Tracking of the installation process of filter equipment

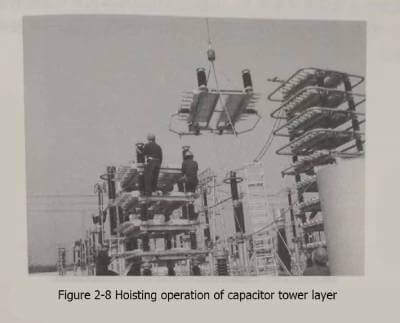

🍍During the installation of capacitor towers, the construction unit should supervise the installation of capacitor towers from time to time according to the equipment number that was trimmed when the capacitor equipment was shipped from the factory. Usually, it is installed layer by layer. Or directly install the insulator of the upper layer on the capacitor layer to be hoisted and hoist together, as shown in Figure 2-8.

🥝During the installation, the construction unit should also be reminded to pay attention to the protection of the finished product. The capacitor porcelain bushing should not be stressed to avoid hidden oil leakage defects, which cannot be exposed in a short time. After the capacitor is put into operation, under the action of the thermal effect, the capacitor will cause oil leakage. occur. At the same time, the supporting insulators should be avoided to be trampled and bruised by tools and tools. It is strictly forbidden for personnel to pass tools and tools by “throwing” up and down during construction. When connecting the wires of the capacitor, connect them tightly according to the torque requirements (currently more common,

🍅The capacitor connector is connected with M16 nut, as shown in Figure 2-9, and the tightening torque is generally 20NM) to prevent the connector from loosening and heating or over-tightening causing oil leakage after the connector is put into operation. Wrench, generally equipped with special tools, instruments, etc. with the equipment, all in the equipment.

🥧The review stage of the technical specification for bidding and procurement is proposed by the operation and maintenance list, or some manufacturers specially configure it for users).

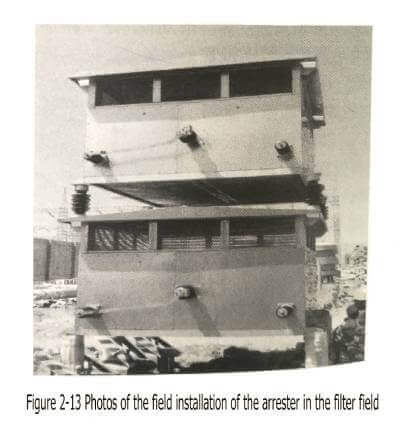

🥇Installation of other equipment; mainly including the installation of filter field resistors, reactors, lightning rods, TA, etc. In addition to urging the construction unit to pay attention to the protection of finished products during the installation process, the following points should also be noted: ①Resistors, reactors Non-ferromagnetic stainless steel bolts and nuts should be used for fixing connection bolts and nuts (clamp connection can be made of galvanized material); ②If the TA in the filter field is oil-filled TA, special attention should be paid to the protection of the unshielded, good, The connection should be reliable, and should be restored in time after the test; ③ all kinds of wire connections should prevent the wire from stressing the equipment; ④ there should be drainage holes at the bottom of the connection of some crimping fittings. As shown in Figure 2-10 to Figure 2-13, the field installation photos of dry-type reactor, resistor, oil-filled TA and arrester are respectively shown.

2.4 On-site debugging and test tracking of filter equipment

🍡On-site debugging and test tracking of filter equipment are generally less used after the equipment is running (unless a tuning test is required after replacing the inductive components), but as on-site operation and maintenance tracking personnel, you are familiar with the most basic debugging knowledge, including Debugging purpose, debugging method, etc.

🍧A set of AC and DC filters must go through a series of calculations, checks, and debugging before and after design, before they leave the factory, in order to play their filtering role in the DC transmission system. The first two phases are generally in the design and manufacturing stages. To play a more ideal role, you must go through on-site debugging and filter debugging. The first is to ensure the safe operation of the system. After debugging, the tuning index and so on meet the design requirements, so as to avoid the resonance of the system and the filter caused by the input of the filter, which will amplify the harmonic current, and also make the overvoltage generated when the filter is input. It is limited within a limited range, so as not to damage other equipment; the second is to ensure the safe operation of the filter itself. After the filter is debugged and put into the system, the harmonic current flowing into the filter will not cause the capacitors and inductors of the filter. , The steady-state overload of the resistor, and the over-voltage and over-current when switching the filter will not cause damage to the components of the filter body.

🍭Inspection before commissioning (usually referred to as cold debugging): After all equipment of the wave generator is installed, a detailed installation inspection is performed on all equipment to ensure that the wiring of each equipment is correct. The general principle of debugging is to change the reactance value by adjusting the distance between the upper and lower coils of the reactor, so that it resonates with the capacitor at the debugging frequency, thus completing the debugging of the filter before it is put into use.

🍹Debugging method: The filter debugging methods include amplitude-frequency characteristic method, discharge oscillation method, and phase-frequency characteristic method. The first two methods have large errors, and the phase-frequency characteristic method is often used in practice. Input the resistor voltage and the total voltage of the filter into two channels of the same filter respectively, and compare the phase angles to determine that the filter is resonant. Usually, the above two voltages are input from different axes (coaxial input, The error is large, which is not conducive to accurate tuning). In the process of observing the two phase changes, the graph is changed from an ellipse to a straight line, and the resonance can be determined, which is easy to observe and has high accuracy.

🥝The main process of phase-frequency characteristic method debugging:

(1) Wiring according to the measurement requirements.

(2) Place a thermometer on site for temperature measurement,

(3) Calculate the tuning frequency under the current situation, whether the tuning frequency of the filter is positive or negative, and what is the difference (positive and negative bias can be determined according to the system impedance).

(4) Turn on the power and adjust the oscilloscope to observe

(5) Adjust the display of the frequency meter and the power frequency of the signal generator (should be the tuning frequency)

(6) Adjust the input voltage of the signal generator, so that the graph of the oscilloscope is easy to observe without distortion, and it is convenient to improve the accuracy.

(7) Adjust the constant separation of the upper and lower coils of the filter reactor (substantially change the mutual inductance of the reactor), and change its reactance value until the oscilloscope graph changes from an ellipse to a straight line.

🥗However, the actual change of the inductance value of the reactor is not continuously adjusted (that is, the distance between the upper and lower coils is divided into steps), so the oscilloscope graph can only be the most approximate straight line in the actual debugging process.

🥘The above method can perform cold-state tuning for high-pass filters and double-tuned velocities, so this method is more practical in engineering. After the filter is debugged by this method, the filter can meet the design requirements and be put into system operation safely and reliably.

🥠Before the debugging and test tracking of the filter, the tracking personnel need to be familiar with the debugging method in advance, master the test steps in the debugging process, and focus on learning debugging wiring and instrument operation during the debugging period.

2.5 Acceptance and acceptance of filter equipment after construction

🔮(1) Acceptance of filters and shunt capacitor equipment (including DC filters) should pay attention to the following general requirements:

1) First of all, the construction unit should complete the construction, first organize the personnel of the unit to self-acceptance, keep the self-acceptance record, and submit to the supervision unit that the acceptance conditions are met after the self-acceptance is passed.

2) The supervision unit begins to organize the acceptance after receiving the notice that the construction unit has completed the self-acceptance and requesting it to organize the acceptance. The acceptance must be organized by the on-site supervision unit, organize the construction unit, the operation and maintenance unit personnel, the design unit and even the manufacturer personnel to participate.

3) The problems found in the acceptance are listed one by one, preferably with photos, and timely feedback for rectification.

4) If it is found that there are many problems of the same type or there are obvious construction quality problems, the acceptance can be stopped. Due to many problems, low-level construction quality problems, etc., the operation and maintenance unit may consider that it does not meet the acceptance conditions, and requires the construction unit to rectify as soon as possible before re-acceptance according to the acceptance process.

5) After the acceptance is completed, the signature procedures of the relevant parties should be completed at the same time. The operation and maintenance unit can completely lock the fence gate of the filter equipment at this time, and it is strictly forbidden for any person to enter the equipment area without authorization.

📿(2) Acceptance content:

1) Visual inspection.

🎆Filters and shunt capacitor device (capacitor towers, inside and outside of resistors, inside and outside of reactors, transformers, arresters, etc.) should be free of residues and should be cleaned. The capacitor tower and other primary connections are correct, and the connection terminals are not loose (check the nut of the capacitor connector M16 with a torque of 20 NM). The grounding place of the equipment should be firm and clearly marked. All equipment insulators, capacitors, current transformers, and lightning arrester porcelain bushings should be clean and free of cracks and damage. The nut, flat washer and spring washer for connecting the lead wire of the capacitor bushing shall be complete. The capacitor shell has no bulging belly deformation, corrosion and other phenomena.

🚀The capacitor frame should be kept in a horizontal position, the pillar insulators should be vertical to the ground, fixed firmly, and the paint should be complete. The capacitors should be installed so that their nameplate faces the channel side and are numbered sequentially. The connecting lines of the capacitor terminals should meet the design requirements, the wiring should be symmetrical and consistent, neat and beautiful, the busbars and branch lines should be marked with the color, and the shells of the capacitors insulated from the ground on each layer of the capacitor tower should be connected to a fixed potential.

🎉The current transformer, the porcelain sleeve has no cracks and damage, the junction box is well sealed, the secondary lead is not stressed, and the plugging is good; the end screen is grounded reliably; the oil-filled TA oil level indication is 1/3-3/4 place. For silicone rubber transformers, the main attention is that the junction box should be well sealed, and the silicone rubber of the primary lead should be well sealed and free of cracks.

🧬Visual inspection of the reactor: The pillar and coil insulation should be free of damage and cracks, the coil should not be deformed, and the pillar insulator and its accessories should be complete. The exposed metal parts of the reactor should have a good anti-corrosion layer and meet the painting requirements for outdoor anti-corrosion electrical products. The inside of the coil is clean and free of debris, and the air duct of the reactor should be clean and free of any debris. In addition, special attention should be paid to the fact that the reactor body and the fixing bolts (nuts) on the bottom bracket should be made of stainless steel (non-magnetically conductive), and galvanized materials should not be used to prevent overheating during operation.

🦠All the above filters (or shunt capacitors)> equipment connection bolts in the forest (except for capacitors that are connected by wire clips or materials, etc., it is clear that the torque inspection cannot be carried out according to the standard torque), use a torque wrench with the corresponding torque. Check to prevent the joints of the equipment from heating up after being put into operation. For the tightening torque of the bolts, refer to the tightening torque table of equipment connecting bolts in Appendix A. It should be pointed out that the bolts fastened according to Appendix A generally refer to the galvanized process (which is used to manufacture bolts in most occasions in the substation) and the bolts with the strength grade clearly marked on the bolts, other materials. For example, there are a considerable number of stainless steel bolts (such as A2-70 material) in the filter field, and in general, the tightening torque of stainless steel bolts of the same diameter commonly used in substations refers to 4.6 grade galvanized bolts. Fixed torque execution.

🎈2)Handover test of equipment in the device. Before the filter and shunt capacitor device is put into operation, the construction unit shall conduct a handover test on all equipment in the filter and shunt capacitor in accordance with GB5050-2006 “Electrical Installation Engineering – Electrical Equipment Handover Test Standard”. The handover test must be qualified, and the test data will be archived and used as the basis for various evaluation and maintenance of the equipment in the future (because when the test score of the equipment state quantity test is carried out, the handover test data is generally used as the initial data of the equipment). In order to ensure the capacitance balance between the DC converter station filter and the capacitor tower bridge arm of the parallel capacitor, an unbalanced current test is generally required to ensure that the unbalance degree meets the requirements.

⚜️3)Acceptance of relay protection device. The filter and shunt capacitor device will be equipped with large group filter protection and small wave filter protection, and the DC filter will be equipped with a DC filter protection device. Before the entry into operation, the protection device should also be checked and accepted at the same time. The inspection of various instructions of the protection device, the verification of the fixed value of the protection device, and the inspection of the protection transmission record of the construction unit should be completed and correct. The specific contents of other acceptance inspections of filters and shunt capacitor protection devices are the same as the acceptance inspections of various protection devices in ordinary AC substations, which can be implemented with reference to relevant regulations, and will not be described in detail in this book.

🔅4)Information to be submitted for equipment acceptance. When the filter and shunt capacitor device is accepted for acceptance, the construction unit shall submit the following materials and documents: manufacturer’s information such as various equipment product manuals, factory test records, qualification certificates and installation drawings provided by the manufacturer; on-site adjustment test records of the construction unit; construction process All kinds of technical documents, meeting minutes, notification rectification orders, etc. occurred in the process; design data files, design change notices, etc.