Description

Standard Snap In Larger Capacitor 680UF 250V

Snap-in capacitors, also known as snap-in electrolytic capacitors, are a specific type of electrolytic capacitor designed with snap-in terminals for easy and secure mounting onto a PCB (Printed Circuit Board). These capacitors are commonly used in electronic devices and systems where high capacitance values and reliability are required. Here are some key features and characteristics of snap-in capacitor 680uf 250v:

Capacitor 680uf 250v Structure: Snap-in capacitors have a cylindrical shape with leads or terminals that have spring-like clips or tabs on the ends. These clips allow for quick and secure mounting onto the PCB, reducing the need for additional hardware such as screws or clamps. The cylindrical body of the capacitor contains the electrolytic solution and dielectric material, typically an aluminum oxide layer.

Electrolytic Capacitance: Snap-in capacitors are primarily known for their high capacitance values. They are available in a wide range of capacitance ratings, typically ranging from several microfarads to thousands of microfarads. This makes them suitable for applications that require the storage and discharge of large amounts of electrical energy, such as power supplies and audio amplifiers.

Capacitor 680uf 250v Voltage Ratings: Snap-in capacitors are designed to handle high voltage levels. They are available with voltage ratings ranging from tens of volts to several hundred volts. It is important to select a capacitor with an appropriate voltage rating that exceeds the expected voltage in the circuit to ensure safe and reliable operation.

Polarized Capacitors: Like other electrolytic capacitors, snap-in capacitors are polarized, meaning they have a positive and a negative terminal. It is crucial to connect them in the correct orientation to avoid damaging the capacitor and the circuit. The positive terminal is usually indicated on the capacitor body or specified in the datasheet.

Capacitor 680uf 250v Applications: Snap-in capacitors are commonly used in various applications, including:

- Power Supply Units (PSUs): Snap-in capacitors are utilized in PSUs for voltage regulation, smoothing, and energy storage.

- Industrial Electronics: They find applications in motor drives, frequency converters, and UPS (Uninterruptible Power Supply) systems.

- Audio Amplifiers: Snap-in capacitors are used in audio equipment to enhance filtering and decoupling for improved sound quality.

- Automotive Electronics: They are employed in automotive systems, such as vehicle power management, motor controls, and infotainment systems.

- LED Lighting: Snap-in capacitors play a role in LED drivers and lighting systems to ensure stable and efficient operation.

Snap-in capacitors provide reliable performance, high capacitance values, and easy installation, making them suitable for demanding applications that require high energy storage and robust electrical characteristics. When selecting a snap-in capacitor, it is essential to consider factors such as capacitance, voltage rating, ripple current capability, and temperature rating to ensure proper functioning in the intended application.

Xuansn factory manufacturering and supply of 2000 to 3000 hours Standard Snap In Larger Capacitor 680UF 250V, its surge voltage is 300v, its Max ESR is 293mΩ and Typ ESR is 205mΩ at 105℃ 120Hz. And its size has 25*50mm and 30*40mm, its ripple current has 1.66mAmrs and 1.76mAmrs at 105℃ 120Hz.

The standard snap in aluminum electrolytic capacitor is suitable for Electric welding machine, Frequency converter, Color TV, computer, Photovoltaic (pv), Instrumentation instrument and Household appliances, ect.

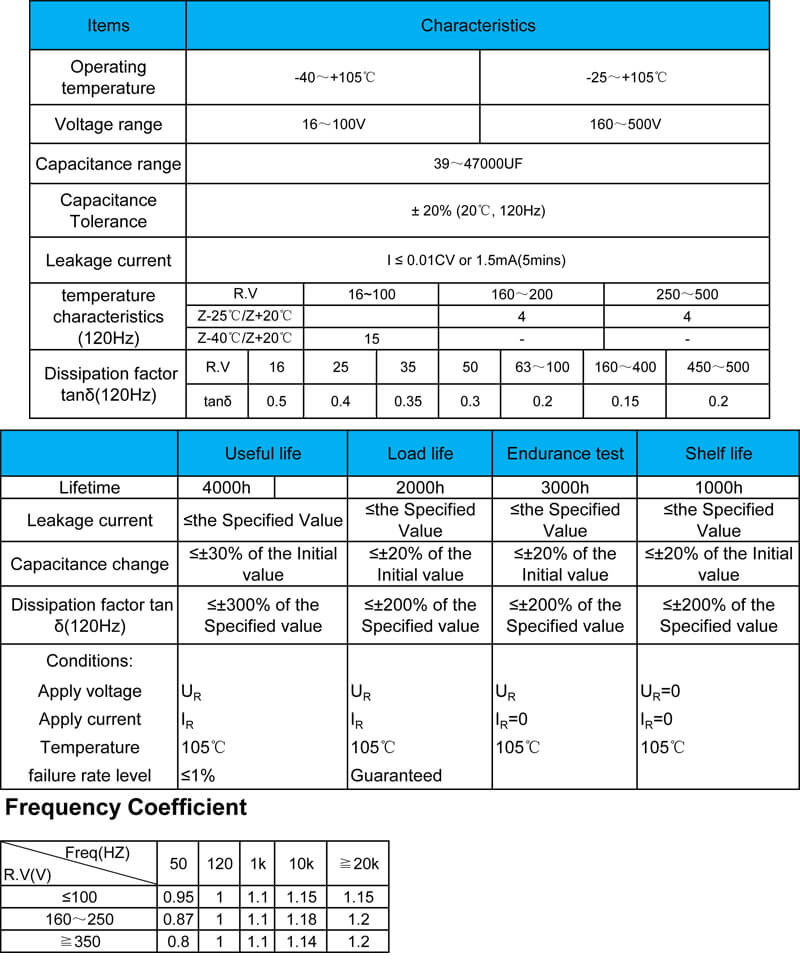

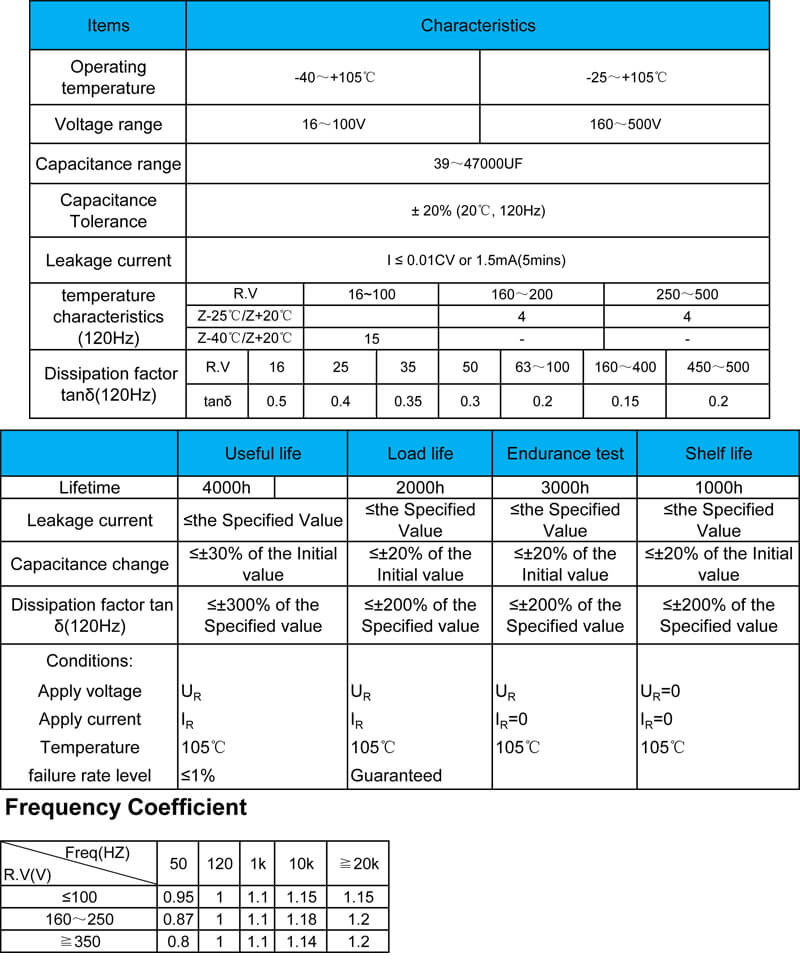

Specification of standard snap in aluminum electrolytic capacitor

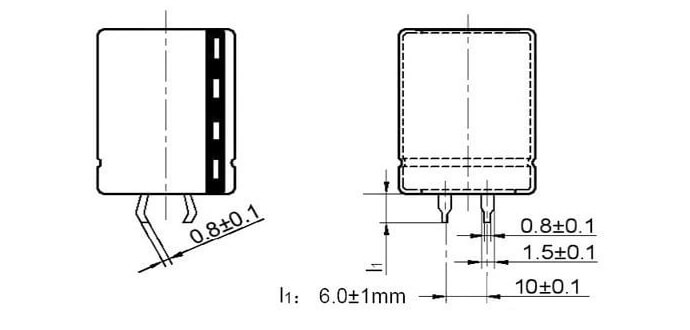

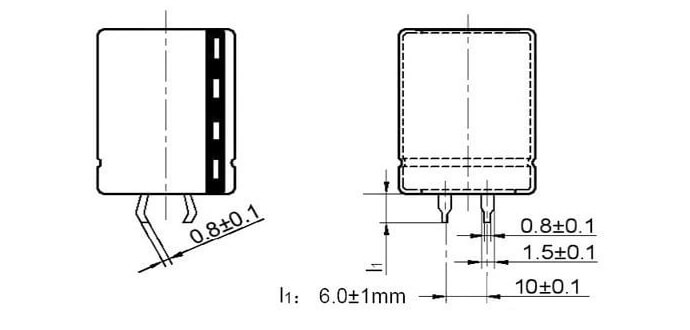

Dimensions(mm)

Product Details

Our certifications

Our advantage:

- We have a sound raw material cooperation system and cargo inspection mechanism.

- Products with high stability, high temperature, small size, small tolerance and so on.

- Product tolerances are strictly controlled between -15% to -10%.

- We have the world’s most advanced production equipment, and improve the management process.

- We can provide custom design of your needs and provide free sample for you.

- Our products comply with the RoHS Directive and the factory conforms to the ISO 9001 management system.

FAQs:

- What is a snap-in capacitor? A snap-in capacitor, also known as a snap-in electrolytic capacitor, is a type of electrolytic capacitor that features snap-in terminals for easy and secure mounting onto a PCB (Printed Circuit Board). The snap-in terminals typically have spring-like clips or tabs that allow the capacitor to be quickly inserted and locked into place on the PCB, eliminating the need for additional hardware like screws or clamps. Snap-in capacitors are commonly used in applications that require high capacitance values and reliable performance, such as power supplies, motor drives, and industrial electronics.

- How do you desolder a snap-in capacitor? To desolder a snap-in capacitor, you can follow these steps:

- Start by ensuring the capacitor is discharged and the power is disconnected.

- Use a soldering iron to heat the solder joints on the snap-in terminals, melting the solder.

- Once the solder is molten, gently apply pressure to the capacitor, releasing the snap-in terminals from the PCB.

- Carefully remove the capacitor from the PCB, ensuring not to damage any surrounding components.

- Clean the solder pads on the PCB with desoldering braid or a desoldering pump to remove any remaining solder.

- What is the lead spacing for snap-in capacitors? The lead spacing for snap-in capacitors refers to the distance between the centerlines of the two snap-in terminals. It is typically specified in millimeters (mm) or inches (in). The lead spacing can vary depending on the specific capacitor model and manufacturer. Common lead spacing values for snap-in capacitors range from 10 mm to 22.5 mm, although other sizes may also be available.

- What causes a capacitor to pop? There are a few reasons why a capacitor may “pop” or fail catastrophically:

- Overvoltage: Subjecting a capacitor to voltage higher than its rated voltage can cause the dielectric to break down, leading to a catastrophic failure.

- Overheating: Excessive heat can cause the electrolyte inside the capacitor to evaporate, leading to increased pressure and possible rupture of the casing.

- Manufacturing defects: Poor manufacturing processes or faulty components can lead to weak points in the capacitor structure, making it more prone to popping under normal operating conditions.

- What happens when a capacitor pops? When a capacitor “pops” or fails catastrophically, it can result in various outcomes depending on the severity of the failure. Common effects include:

- Loud noise: The sudden release of pressure and energy can produce a loud popping or cracking sound.

- Emission of smoke or odor: If the capacitor is filled with electrolyte, it may release smoke or emit a distinct odor when it fails.

- Casing rupture: The pressure buildup inside the capacitor can cause the casing to rupture, releasing the internal components and electrolyte.

- Circuit damage: The failure of a capacitor can cause damage to surrounding components, circuit traces, or PCBs due to the release of energy, smoke, or debris.

- What are three common faults with capacitors? Three common faults or issues that can occur with capacitors are:

- Capacitance drift: Capacitors may experience a change in their capacitance value over time, leading to a deviation from the specified tolerance range.

- Leakage or high ESR: Capacitors can develop internal faults that result in increased Equivalent Series Resistance (ESR) or leakage current, impacting their performance and causing power loss or instability in the circuit.

- Short circuit: In some cases, capacitors can develop internal faults that result in a short circuit between their

If you have any interesting and problems, please contact us!

Email: [email protected]

Ph (whatsapp): +86-18825879082

Skype: Coco.PSH