⭐️Paper dielectric film capacitors are the earliest film capacitors. They are wound capacitors with capacitor paper as the medium and aluminum foil as the electrode. They are available in sealed and semi-sealed structures.

⭐️The dielectric coefficient of capacitor paper is about 2.2. Because it is made of plant cellulose, it is porous, and generally contains 20% to 35% (volume) of air and 5% to 7% (weight) of moisture. Therefore, when manufacturing capacitors, drying and immersion must be carried out to remove moisture. Dipping is usually filled with liquid (capacitor oil) or solid (paraffin) with high dielectric coefficient and dielectric strength to improve dielectric coefficient and dielectric strength.

✨Advantages of paper dielectric capacitors:

The capacitance and working voltage range is very wide, the process is simple, the cost is low, and it is easy to metalize. The current paper medium is usually combined with an organic medium to take full advantage of the good metallization performance of the paper medium to make a capacitor with excellent performance such as a double-metallized capacitor.

⚡️The disadvantages of paper dielectric capacitors are:

The purity of the capacitor oil or paraffin determines the insulation resistance of the paper dielectric capacitor. Once the capacitor oil is acidified or other factors that cause the insulation resistance to decrease, the insulation resistance and dielectric strength of the paper dielectric capacitor will be destroyed.

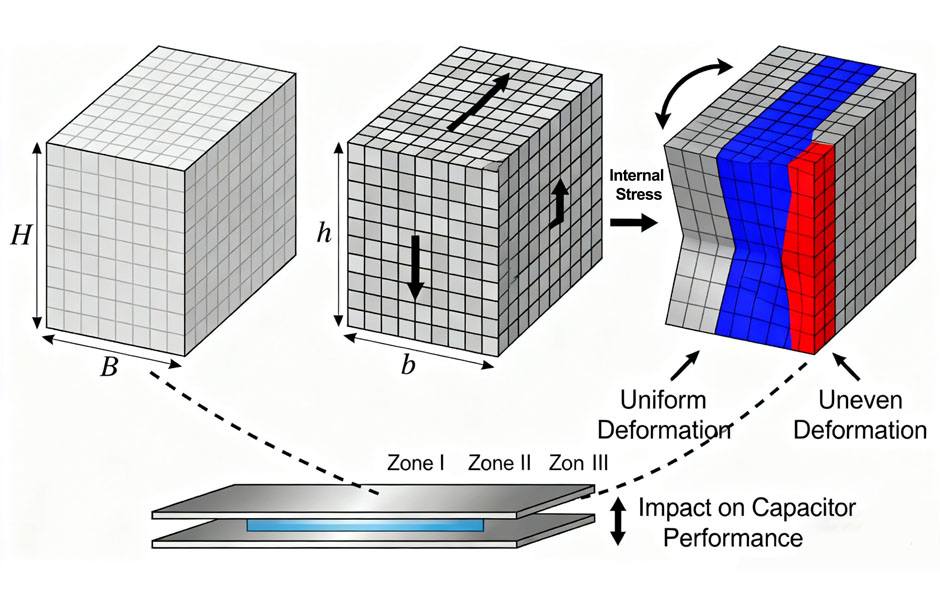

Since the capacitor paper is a porous plant fiber, even if it is impregnated with capacitor oil or paraffin, the non-porous metalized electrode may cause some weaknesses of the capacitor, although the self-healing performance of the metalized electrode can eliminate the weakness of the metalized capacitor when a local breakdown occurs. However, the insulation resistance of metallized paper dielectric capacitors is generally lower than that of organic film metallization.

⭐️In spite of this, paper dielectric capacitors are still used in a large number of applications. The main reason is that paper dielectric is most suitable for metallized electrodes. In other words, various dielectric film metallized electrodes, and paper dielectric metallized electrodes have the best quality. Moreover, the paper media film does not become soft at high temperatures is another advantage of paper media.✨