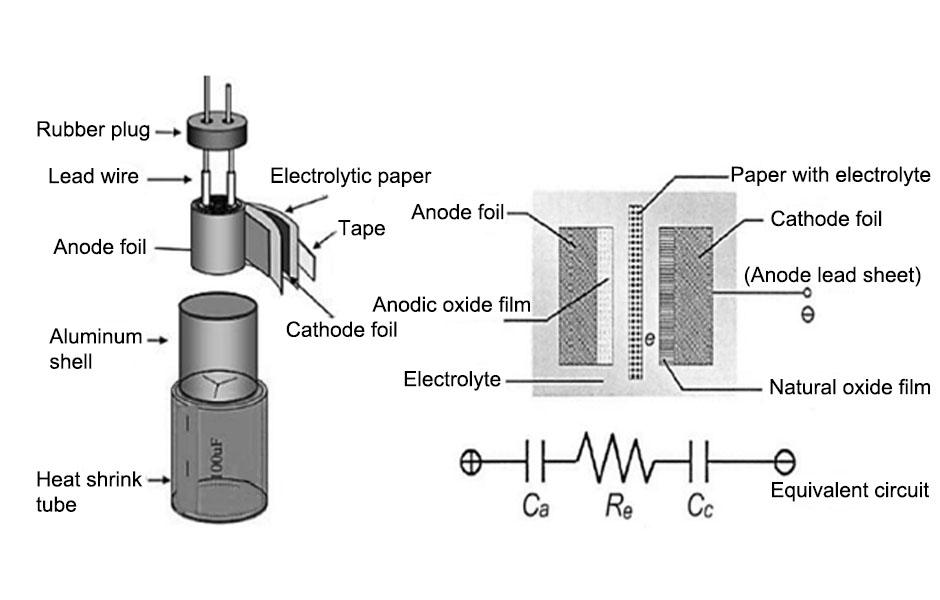

Aluminum electrolytic capacitors are made of aluminum cylinders as negative poles, which are filled with liquid electrolyte, and a curved aluminum strip is inserted as positive poles. Common sense of the use of aluminum electrolytic capacitors includes the following points:

1. The DC electrolytic capacitor can only be used on a DC circuit, and its polarity must be marked in an appropriate position or next to the guide pin/terminal.

2. If the polarity of the circuit is unclear or unclear in the circuit loop, it is recommended to use a non-polar electrolytic vessel.

3. The working environment temperature of the electrolytic capacitor cannot exceed the specified use temperature range.

4. The electrolytic capacitor should be stored in a low temperature and dry place. If the storage period is longer, the rated voltage should be used to re-sophisticate it before use.

5. The ripple current through the electrolytic capacitor should not exceed its allowable range. If it exceeds the specified value, an electrolytic capacitor resistant to large ripple current needs to be selected.

6. When used, the working voltage of the electrolytic capacitor should not exceed its rated voltage.

7. High-temperature heating devices such as electric soldering irons should be kept at an appropriate distance from the plastic casing of the electrolytic capacitors to prevent the plastic sleeve from rupturing due to overheating.

8. When welding aluminum electrolytic capacitors, the welding time and welding temperature should not exceed 10 seconds and 260 degrees Celsius.

9. If excessive force is applied to the guide pins and terminals, the internal structure of the electrolytic capacitor will be destroyed.