choose aluminum electrolytic capacitors: capacity, withstand voltage, temperature range, component package form and size, ripple current, ripple voltage, leakage current, ESR, dissipation factor, impedance / frequency characteristics, capacitor life, actual needs, performance and cost And other comprehensive considerations.

Through investigating the problems encountered by engineers in selecting aluminum electrolytic capacitors and applications, it is also necessary to pay attention to the stability of aluminum electrolytic capacitors to the entire circuit when selecting aluminum electrolytic capacitors.

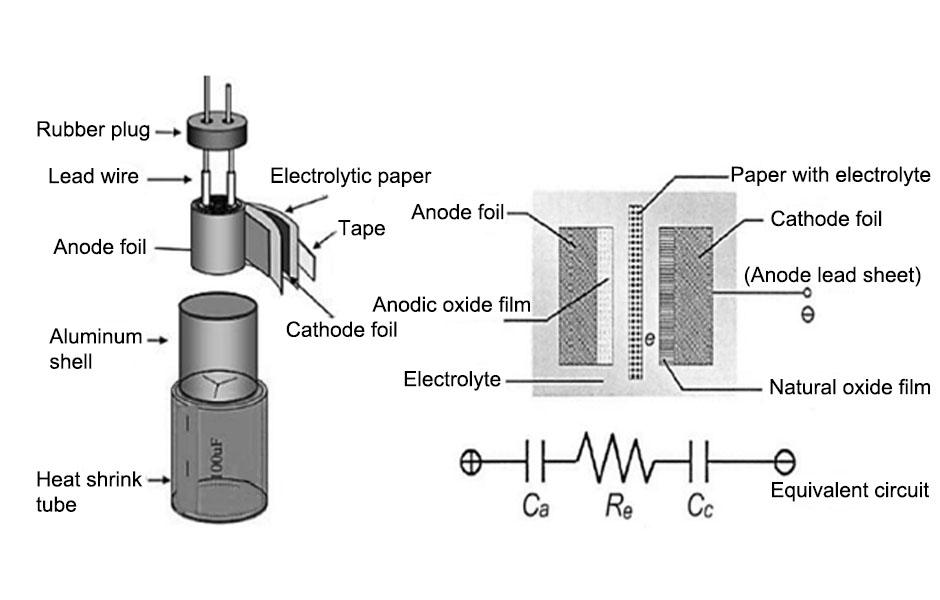

Aluminum electrolytic capacitors are polar capacitors composed of etched high-purity aluminum foil as the anode and thin paper or cloth impregnated with the electrolyte as the cathode. Advantages: large capacity, high withstand voltage, cheap price Disadvantages: large leakage current, large error, poor stability, and life decreases rapidly with increasing temperature. Aluminum electrolytic capacitors used in digital circuits are generally used for smooth power supply filtering. In addition to well-known parameters such as capacity, withstand voltage, capacity error, operating temperature, package size, etc., there are several important parameters related to capacitor quality, including loss angle. Tangent, leakage current, equivalent series resistance ESR, allowable ripple current, service life, etc.

Aluminum electrolytic capacitors are polar capacitors composed of etched high-purity aluminum foil as the anode and thin paper or cloth impregnated with the electrolyte as the cathode. Advantages: large capacity, high withstand voltage, cheap price Disadvantages: large leakage current, large error, poor stability, and life decreases rapidly with increasing temperature. Aluminum electrolytic capacitors used in digital circuits are generally used for smooth power supply filtering. In addition to well-known parameters such as capacity, withstand voltage, capacity error, operating temperature, package size, etc., there are several important parameters related to capacitor quality, including loss angle. Tangent, leakage current, equivalent series resistance ESR, allowable ripple current, service life, etc.

The stability and reliability of the circuit system performance is closely related to the selection of parameters, grades, and quality of aluminum electrolytic capacitors. When choosing the aluminum electrolytic capacitor, the designer should accurately put forward the specific requirements for the component parameters according to the product application environment and electrical performance requirements, including the nominal value, accuracy and error requirements, stability requirements, temperature range requirements, and installation dimensions. And other requirements that are closely related to circuit performance. Because of the highest failure rate of aluminum electrolytic capacitors among all passive components, how to choose aluminum electrolytic capacitors is particularly important.