Investigate the secret of “longevity” of aluminum electrolytic capacitors

In order to prevent global warming, LED lighting (Light Emitting Diode) as a means of saving energy has attracted attention. LED has been applied and developed in many fields, especially to prevent global warming caused by lighting products, CO2 reduction, energy saving and other means, LED will gradually replace incandescent lamps, energy-saving lamps and get development. The biggest feature of LED is to save energy and long life. The components used are also required to be small and reliable, and are valued and developed.

LED lighting products use non-solid aluminum electrolytic capacitors (hereinafter referred to as aluminum electrolytic capacitors). Compared with other capacitors, it has the characteristics of wider use temperature, small size, large capacity, and cheap price, but its disadvantage is that its life is limited. Aluminum electrolytic capacitors have become indispensable components of LED lighting products, but the reason of capacitor life will affect the life of finished products

The longevity of aluminum electrolytic capacitors is a major issue. Every capacitor manufacturer has been researching. The capacitor brand Rubycon, which is a Fujitsu agent, has developed a highly reliable electrolyte using years of accumulated experience and technology. Long-life LLE series

The necessity of prolonging the life of aluminum electrolytic capacitors

The life of aluminum electrolytic capacitors is greatly affected by temperature. When the temperature around the capacitor decreases, the life of the product will be extended. For this reason, in the circuit design, in order to meet the life requirements of the product, the layout of the components is on the one hand, it is also important to reduce the ambient temperature of the capacitor. However, due to the compact components of LED products (especially bulb LEDs), it is very difficult to consider the layout of the components so that their lifespan meets the requirements. Bulb LED lighting uses 105 degrees 10000h capacitors sometimes difficult to meet the life requirements, requiring longer life capacitors.

Features of Rubycon LLE series

The LLE series is mainly developed for the LED bulb market with long life requirements. The characteristic of this series is that the pressure is 160V~400V, the size is Φ6.3×11L~Φ10×16L, the industry’s longest life span is 12,000h~20,000h. Table-1 lists the life comparison between the LLE series and the more long-life BXC series used in the market. The LLE series has developed a smaller size product system based on the previous long-life product BXC. Under the same size, LLE has achieved a long life of 1.8 to 2 times that of BXC.

Selecting LLE series products can achieve the following purposes:

(1) It can also meet the requirements of long life in severe use environment.

(2) General aluminum electrolytic capacitor products are forced to choose MLCC or film capacitors because they cannot meet the life requirements of the equipment. The LLE series will effectively solve the problem of life and reduce the cost of components.

(3) In order to meet the service life requirements of the product, the electrolytic capacitors of a larger size need to be selected before. The LLE series will solve this problem and realize the miniaturization of the product.

(4) When the internal heat of the product is large, solutions such as capacitor layout (placement) and heat dissipation should be considered. The LLE series makes the circuit design simple and compact.

Technical elements of LLE series long life

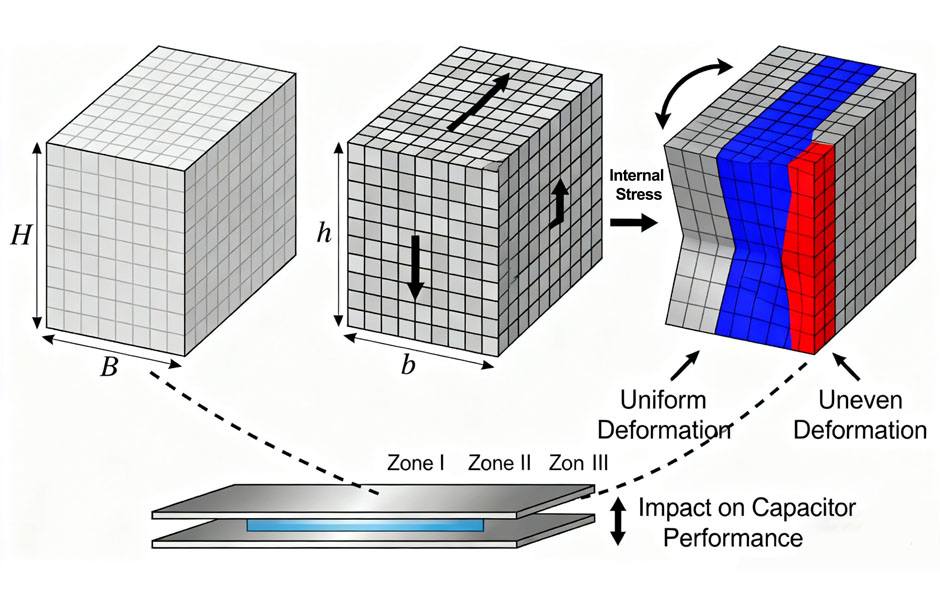

Aluminum electrolytic capacitors are mainly affected by the evaporation of the sealing rubber through the evaporation of the sealing rubber and the changes in the characteristics of the electrolyte. Therefore, as a countermeasure, to maintain the life of the electrolytic capacitor, it is necessary to prevent the evaporation of the electrolyte and the characteristics of the electrolyte. Change and maintain the proper amount of electrolyte in the capacitor.

The electrolytic solution used in aluminum electrolytic capacitors contains a variety of solvents, among which ethylene glycol is the main solvent, which has been researched and developed by various manufacturers, and has been accumulated and designed in accordance with their respective experiences. Rubycon has used more than 50 years of electrolyte development technology, combined with relevant technical experience, to develop a long-term stable electrolyte under high temperature cycle, and applied to the LLE series. Compared with the general standard products, the electrolyte has a characteristic change rate reduced to less than 1/3 under a high temperature environment for a long time, which minimizes the thermal aging of the electrolyte.

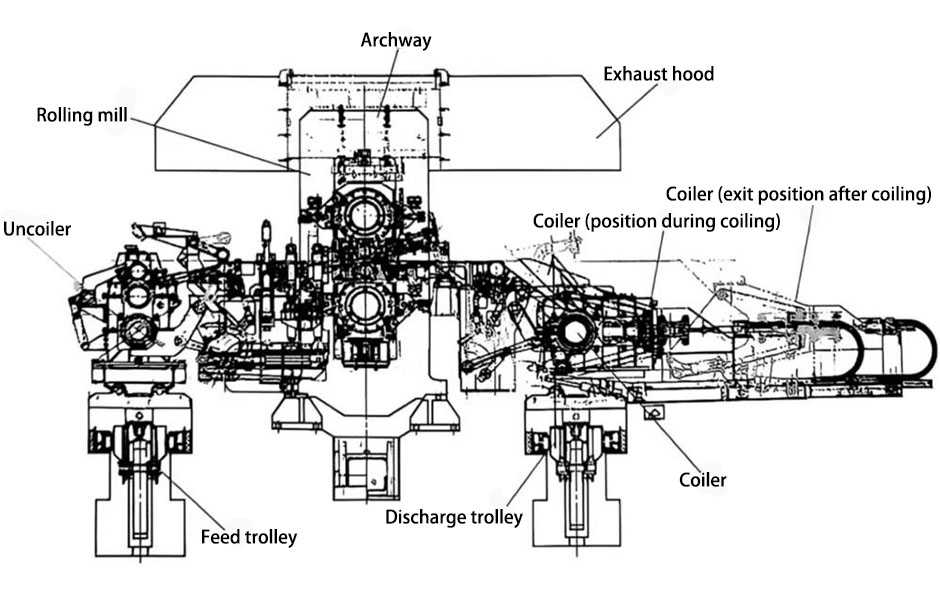

In addition, the sealing rubber with better airtightness is selected to cooperate with the above electrolyte to achieve the best match. Moreover, the production equipment developed by our company is used to control the injection amount of electrolyte with high precision to ensure the stable consumption of electrolyte.

The LLE series integrates materials, product design, production equipment and other technologies, and achieves ultra-long life.

The miniaturization of the product increases the internal heating of the product, which puts forward requirements for the long life of the components. Aluminum electrolytic capacitors are devices with limited lifespan, which will affect the life of the product. However, due to the large capacity demand and the low price per unit capacity, they are used by most products. The long life of aluminum electrolytic capacitors is a key device to ensure the long-term reliable operation of products. Therefore, as a long-term topic, it is continuously developed and developed. In the future, Rubycon will ensure and develop the advantages of aluminum electrolytic capacitors and promote the development of longer life of aluminum electrolytic capacitors.