1. The current market for aluminum foil materials for aluminum electrolytic capacitors has a high degree of prosperity. Can it continue?

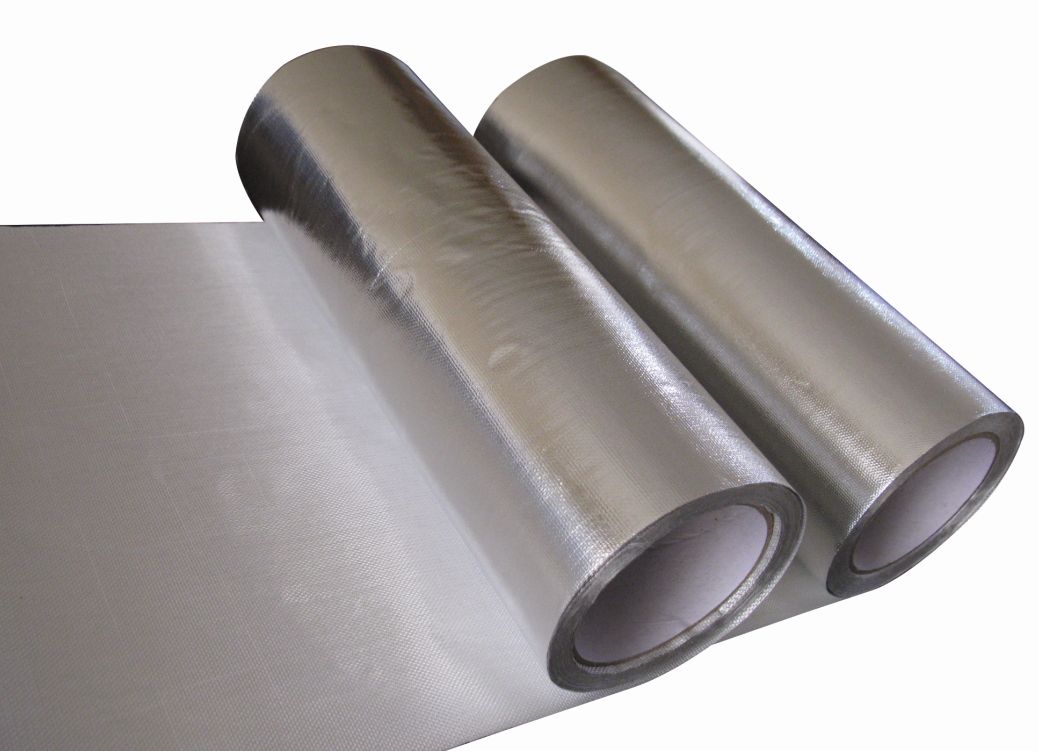

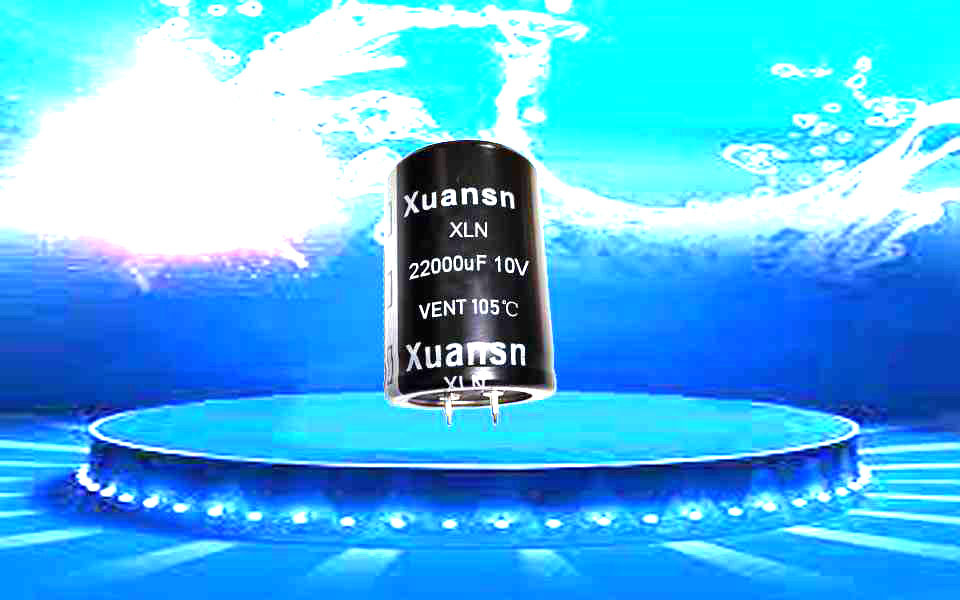

A: In terms of demand, the global electronic information industry has developed rapidly, which has greatly promoted the development of aluminum electrolytic capacitors and their downstream industries. It is used in the fields of energy-saving lighting, consumer electronics, automotive industry, communication electronics, electromechanical equipment, aerospace and other fields. The demand for capacitors is rapidly increasing. As a key raw material for aluminum electrolytic capacitors, electrode foils have shown a growing trend in market demand. On the supply side, due to the large amount of acidic wastewater and irritating gases emitted during the electrode foil production process, the electrode foil industry The requirements for environmental protection investment and pollutant discharge permit are relatively high. In 2017, China continued to vigorously implement supply-side reform and environmental protection supervision, strictly controlling the amount of wastewater treatment, resulting in production capacity of some of the smaller production capacity and production of irregular electrode foil enterprises, limited to environmental protection technology and The scale of production, the above-mentioned production and production of electrode foil foil enterprises are also less likely to resume production, so the electrode foil supply end has a more obvious tension. In 2017, the average price of the company’s electrode foil products was about 57 yuan / square meter (excluding tax price), and in May 2018, the average price of the company’s electrode foil products reached about 62 yuan / square meter (excluding tax price). As demand continues to grow, the regulated supply capacity growth is relatively slow, and it is expected that the market will continue to maintain a high degree of prosperity for a long period of time in the future.

2. What is the company’s electricity consumption and cost?

A: The company has a 2*150MW cogeneration unit, which can meet most of the electricity demand in the Ganquanbao Park, and is insufficient for outsourcing. Affected by the increase in coal prices, the power generation cost of 2*150MW cogeneration units has increased; as the demand for electricity has increased, the amount of purchased electricity has increased, and the cost of integrated electricity has increased.

3. The company plans to expand the production capacity of corroded foil and foil into foil. Can the market be guaranteed?

A: As mentioned above, due to the growth in demand for new energy and energy-saving lighting, the demand for aluminum electrolytic capacitors will increase and will continue to grow. At the same time, the demand for new areas requires higher quality and technical level of electrode foil products. Only companies with certain technical level and quality management capabilities can meet this market demand. As a leading electrode manufacturer of aluminum electrolytic capacitors with leading technology and leading technology, the company has various conditions in terms of R&D level and quality management, and the new production projects have the advantage of electricity price and cost, which can guarantee the market of new capacity.

4. Profitability and competition of major products?

A: Due to the market supply and demand and the improvement of the company’s technical capabilities, the company’s electrode foil, electronic aluminum foil, high-purity aluminum products have improved profitability, and are in the forefront of the electrode foil field, leading the market in the field of electronic aluminum foil and high-purity aluminum. The company’s alloy products and aluminum products are mainly based on the price of aluminum. The decline in aluminum prices is not conducive to the profitability of products. However, the company is constantly adjusting its product structure, improving product profitability and reducing the impact of aluminum price fluctuations on product profitability. Alloy plate ingots have strong competitiveness and advantages, and other aluminum alloy products and aluminum products are more competitive in the market.

5. How is the progress of the company’s graphene aluminum alloy wire rods?

A: The company is continuing to improve the related technologies and products of graphene aluminum alloy wire rods. It has not yet had the network testing and industrial production conditions in the power grid.