1 The purpose of modification of capacitor casting

Whether it is capacitor casting ingot or cast-rolled strip, the shape and size of its grains will affect the subsequent processing performance and the organization and mechanical properties of the finished product. Coarse grains will deteriorate these properties. Therefore, to produce high-performance and high-quality aluminum processing products, it is necessary to first obtain a fine and uniform grain structure. To obtain such a structure, it is not possible to simply rely on the spontaneous nucleation, growth, and crystallization of metastable fluids (of course, it is not possible to completely eliminate uniform nucleation in the aluminum melt); instead, the body must be modified. Especially for direct casting and casting of electrolytic aluminum liquid, modification is particularly important. Whether the melt purification and modification and refinement of electrolytic aluminum liquid can be done well is the key to whether high-quality plate, strip and foil can be produced.

The grain size of cast ingots and cast-rolled strips is determined by the number of crystal nuclei in the melt during crystallization and the speed of grain growth. The more crystal nuclei there are, the slower the grain growth rate, and the finer the grain. Therefore, when casting or rolling capacitors, in order to make the melt have as many crystal nuclei as possible, it is not entirely dependent on the spontaneous nucleation of the melt and the active crystal cores in the melt, but it is necessary to add certain special substances to the melt. These substances contain certain insoluble compound particles, which have a certain coherence relationship with the aluminum grains and can serve as external crystal cores of the aluminum melt to refine the grains; or some special methods are used to break the dendrites at the crystallization front and distribute the broken crystals into the melt to become crystal cores, thereby achieving the purpose of grain refinement.

The grain size of cast ingots and cast-rolled strips is determined by the number of crystal nuclei in the melt and the rate of grain growth during crystallization. The more crystal nuclei there are, the slower the grain growth rate is, and the finer the grains are. Therefore, when capacitor casting or casting, in order to make the melt have as many crystal nuclei as possible, it is not entirely dependent on the spontaneous nucleation of the melt and the active crystal cores in the melt, but it is necessary to add certain special substances to the melt. These substances contain certain insoluble compound particles, which have a certain co-lattice relationship with aluminum grains and can serve as external crystal cores of aluminum melts to play a role in grain refinement; or some special methods are used to break the dendrites at the crystallization front and distribute the broken crystals into the melt to become crystal cores, thereby achieving the purpose of grain refinement.

2 Types and modification methods of capacitor casting modifiers

Grain refiners include:

(1) Aluminum-titanium master alloy. Contains 3% to 5% titanium and has a good refining effect on the casting structure.

(2) Aluminum-zirconium master alloy. Contains about 3% zirconium and has a good refining effect on the casting structure. It is used for some alloys that require welding performance to improve the weld structure performance.

(3) Aluminum-strontium master alloy. Contains about 5% strontium and is used to refine the primary silicon of high-silicon alloys.

(4) Aluminum-titanium-boron master alloy. The titanium and boron contents vary. Commonly used ones are A1-5%Ti-1%B, A1-3%Ti-0.6%B, A1-3%Ti-1%B, etc., which are indispensable refiners for current cast and rolled billets.

(5) Aluminum-titanium-boron rare earth master alloy. A certain amount of rare earth elements (mainly cerium, neodymium, etc.) are added to aluminum-titanium-boron to extend the effective action time of aluminum-titanium-boron.

(6) Aluminum-titanium-carbon master alloy. It is used for cast and rolling modification in capacitor casting and has a good modification effect, but the modification process requirements are relatively strict.

Other modification methods include:

(1) Ultrasonic vibration method. The alternating transformation of ultrasonic sparse and dense waves is used to break the dendrites and introduce “foreign cores”.

(2) Electromagnetic oscillation method. The principle of electromagnetic force is used to break the dendrites at the front of the crystallization to make them the crystallization core.

(3) Mechanical vibration method. Use mechanical vibration to break dendrites as crystallization cores.

These three methods have been reported in experiments, and the effect of grain refinement is relatively obvious, especially electromagnetic casting and rolling. When the magnetic field strength reaches a certain level, it can replace aluminum titanium boron to obtain uniform and fine equiaxed crystal structure. However, because some technical problems in production have yet to be solved, it has not yet been put into industrial production.

3 Modification and refinement mechanism of aluminum titanium and aluminum titanium boron

In aluminum alloy casting and rolling, the most commonly used and most effective modifier is aluminum titanium boron intermediate alloy, followed by aluminum titanium carbon intermediate alloy. The use of aluminum titanium boron intermediate alloy to refine grains has achieved great success in production practice, but the research on its refinement mechanism has not yet been fully understood and there is no unified understanding. There are many theories, which can be summarized into two theories:

(1) Heterogeneous nucleation theory, which believes that titanium undergoes peritectic reaction in the melt to generate TiAl3, TiB2 and other particles as heterogeneous crystal nuclei. There is a coherent relationship between TiAl3 and aluminum lattices, which increases the melt core and nucleation rate and refines the grain structure;

(2) α-Al crystal growth theory, also called segregation coefficient theory, which believes that the segregation coefficient | 1-k | of titanium is the largest, the solute segregation is the most serious before the solid-liquid interface, and the necking of the crystal formed on the mold wall is also the most severe, which is easy to be free to produce crystal proliferation. When titanium and boron are added at the same time, the number of free primary crystals increases, thereby improving the refinement effect.

4 Requirements and addition methods of modifiers

Different modifiers have different addition methods.

Although the same alloy is used as a modifier in aluminum-titanium sintering, the refinement effect is obvious, but in terms of casting and rolling, there are very strict requirements on its composition, structure and addition process. In the capacitor casting process, the content of titanium and boron in the same alloy of iron and boron varies. Commonly used A1-5%Ti-1%B, A1-3%Ti-0.6%B, A1-3%Ti-1%B, etc., the iron content is required to be less than 0.2%, the silicon content is less than 0.35%, and the titanium and boron content are required to be controlled within a strict proportion range; slag inclusions are not allowed in the material; TiAI3 is in block form, and its size is required to be within a certain range; the distribution must be uniform; TiB2 lumps are small in size and are dispersed. If these requirements are not met, especially when TiAI3 is in needle-like shape, the refining effect will be significantly reduced for the casting and rolling strip, and sometimes there is basically no refining effect.

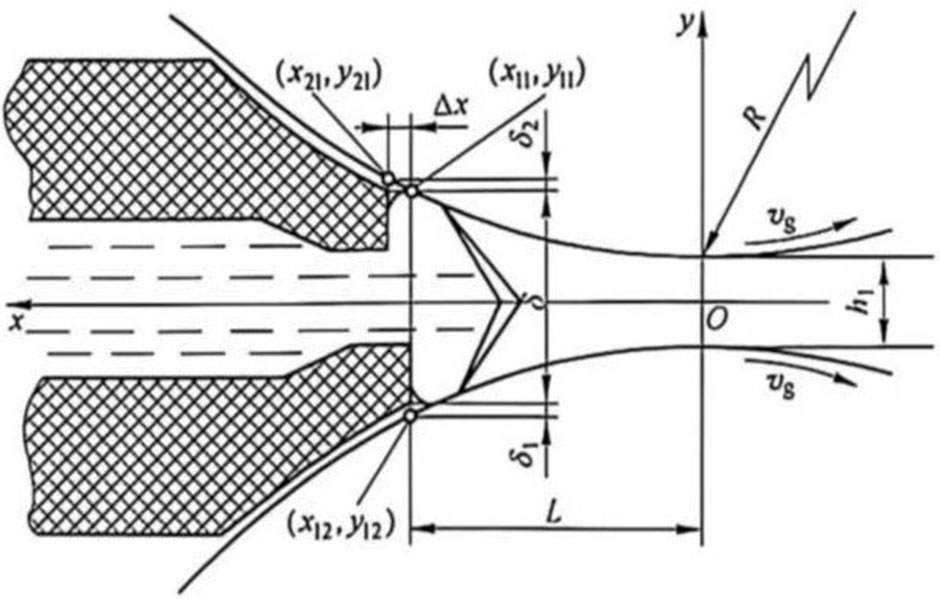

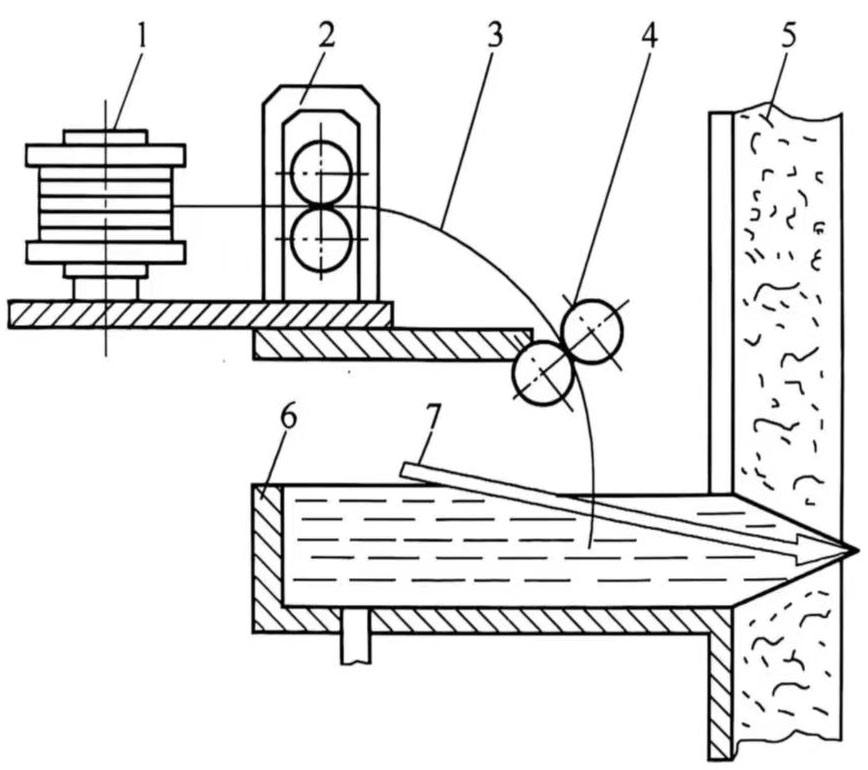

The effective time of aluminum-titanium-boron master alloy is short. From the addition of aluminum melt to the crystallization and solidification of aluminum melt, the refining effect is good in about 10 minutes, and it cannot exceed 30 minutes. If it exceeds 30 minutes, the refining effect will be significantly weakened: the main reasons are: (1) the particles as foreign cores are passivated; (2) these particles may precipitate, reducing the active core particles or losing the nucleation function. Therefore, it can only be added online with a special device and cannot be used indoors. The structure of the adding device is shown in Figure 1.

The modifier adding device is driven by a micro DC motor, and a delivery roller with a groove is conveyed by a reducer. There is a clamping device above the delivery roller, which can bite the aluminum iron boron wire and send it to the front of the flow or the pass box. The amount of aluminum iron boron wire added can be freely adjusted by adjusting the motor running speed.

Figure 1 Refining wire adding device

1-wire rack; 2-delivery machine; 3-alloy wire; 4-middle guide roller: 5-static furnace; 6-flow trough; 7-plug

In the capacitor casting process, the temperature cannot be too low when adding aluminum titanium boron wire. This is because the aluminum titanium boron wire absorbs more heat during melting. If the temperature is too low, the melting is not sufficient, which increases the viscosity of the aluminum wave and reduces the refinement effect. However, if the temperature is too high, the supercooling degree of the aluminum liquid during crystallization is reduced, which deteriorates the casting and rolling process conditions and weakens the refinement effect. When using a corundum tube to filter aluminum melt, sometimes due to the high precision of the corundum tube, TiAl3, TiB2, BAl2 and other particles may be filtered out, which weakens the refinement effect. If this happens, it can be added after filtering, but care should be taken to prevent slag formation and insufficient melting when the modifier is added.

5 Modifier addition amount

The purpose of adding modifiers is to refine the grains. Therefore, as long as the grains are refined to the first-level grains, it is not the case that the more you add, the better. If too much is added, the price of the modifier is higher, which increases the cost; the content of hard and brittle phase particles such as TiAl3, TiB2, etc. is higher, which will change the mechanical properties of the material and reduce plasticity. During the capacitor casting process, excessive addition may cause pinholes in the double zero aluminum foil and increase the black and white stripe defects of the PS aluminum plate base. On the basis of refining the grains, the less the better. For aluminum titanium boron wire containing 5% Ti and 1% B, the addition amount is about 0.15%.