🎇Low purity aluminum foil is used for the negative electrode.

If the aluminum component does not reach the purity of 99.9%, based on cost considerations, it can still be used for cathode aluminum foil, because the purity of the cathode aluminum foil only needs to reach the level that it will not be corroded by the working electrolyte.

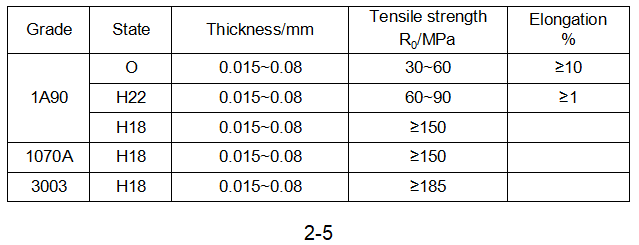

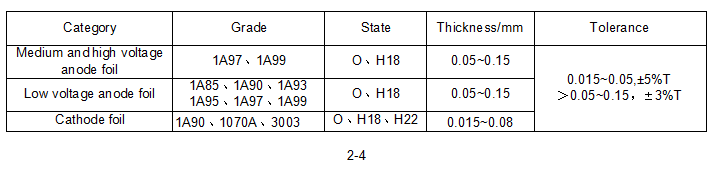

According to the standard of aluminum foil for electrolytic capacitors GB/T 3615-2016, the recommended brand numbers of cathode aluminum foil are 1A90 (aluminum content﹥99.90%), 1070A (aluminum content﹥99.70%), 3003 (aluminum content﹥97%), for general products In other words, price and tensile strength are the key considerations. Aluminum foil with a purity of 97%-98.4% can be selected. As for products with higher requirements for life and charge and discharge frequency, it is necessary to have good corrosion effect and electrolyte stability. Consider the important point, you can choose aluminum foil with a purity of 99.9%.

High specific capacitance cathode aluminum foil often uses alloy foil to improve the specific capacitance effect. For example, the aluminum foil of brand 3003 adds Mn (content 1%~1.5%) and Cu (content 0.05%~0.2%) to the aluminum material. Improve the strength of aluminum foil and improve the effect of corrosion specific capacitance.

🎇Specifications of electronic aluminum foil.

According to the standard GB/T 3615-2016 for aluminum foil for electrolytic capacitors, China specifies the brand, state and thickness specifications of electronic aluminum foil, as shown in Table 2-4.

Note: Ο represents the soft foil after annealing, H18, H22 represents the hard foil with different tensile strength.

The thickness of electronic aluminum foil for electrolytic capacitors is constantly changing with the miniaturization of capacitors, the demand for high specific capacitance and the improvement of corrosion technology. The thickness of anode aluminum foil is getting larger and the thickness of cathode aluminum foil is getting smaller and smaller. In the 1980s, the thickness of the anode aluminum foil was mostly 65 μm, 75 μm, 85 μm, 95 μm and 104 μm, and the thickness of the cathode aluminum foil was mostly 30 μm, 40 μm, 50 μm. After entering the 21st century, the thickness of anode aluminum foil has increased to 108μm, 112μm, 118μm, 120μm, or even 130μm, of which 120μm is the most used. The thickness of the cathode aluminum foil is reduced to 15μm and 20μm, of which 20μm and 50μm are used the most.

According to the adaptability, compatibility and versatility of corrosion and energizing equipment, the current width of electronic aluminum foil for electrolytic capacitors in the world is mostly 500±1mm.

The medium and high voltage anode aluminum foil adopts the DC tunnel corrosion method. The cubic texture degree is required to be greater than 90% for the anode foil with a thickness of 0.085~0.100mm, and the cubic texture degree is required to be greater than or equal to 95% for the anode foil with a thickness of 0.100~0.150mm. Therefore, the high and medium voltage anode foil must be a soft aluminum foil that has been annealed in a high temperature vacuum or inert atmosphere at about 600°C.

Low-voltage anode aluminum foil has both the corrosion method developed by DC-hole AC and the pure AC corrosion method. Therefore, the low-voltage anode aluminum foil can use either soft aluminum foil or hard aluminum foil.

Most of the cathode aluminum foil is chemically corroded. Because the hard aluminum foil has a large number of rolled and broken grains and the grain boundary energy is large, it is very helpful to increase the corrosion rate and increase the specific capacitance of the corroded aluminum foil. Therefore, most of the cathode aluminum foil uses hard State aluminum foil.

🎇Mechanical indicators of aluminum foil.

The standard of aluminum foil for electrolytic capacitors only has indicators for the tensile properties of the cathode aluminum foil at room temperature, and there is no specification for the anode aluminum foil, which shall be determined by both parties through consultation. The Chinese aluminum standard for electrolytic capacitors GB/T 3615-2016 has two indicators for the tensile mechanical properties of cathode aluminum foil at room temperature, tensile strength and elongation. Specific indicators are shown in Table 2-5.