1 Introduction The Application Of AC Capacitor

The application of AC capacitor in air conditioning is very important.It is one of the core components of the air conditioning system. It is usually used as the starting and running capacitor of the compressor motor and the fan motor, and plays an important role in the starting and operation of the compressor and the fan motor. Once the capacitor fails, the air conditioner will not work properly. Therefore, whether the AC motor capacitor is reliable and whether the selection is reasonable directly affects the performance and safety of the air conditioner. In the development and design of the air conditioner, we must pay attention to the reasonable selection of capacitors, and special attention should be paid to the requirements for explosion protection.

2 The Application of AC capacitor in air conditioners

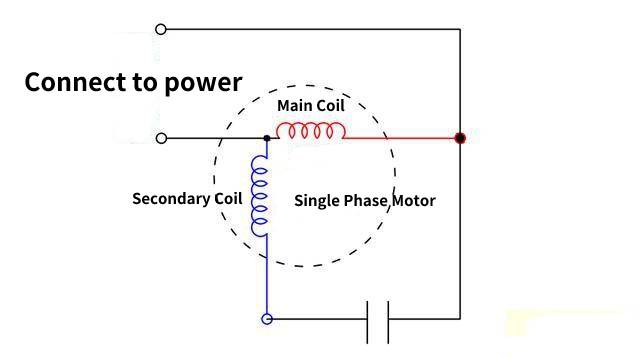

AC capacitors are usually used as the starting and running capacitors of compressor motors and fan motors, and play an important role in the starting and operation of compressors and fan motors. For air conditioner compressor motors and fan motors, single-phase capacitor-operated asynchronous motors are the most commonly used. When a single-phase asynchronous motor works, it does not have only one phase winding, because one winding cannot generate a rotating magnetic field, and the motor cannot rotate. According to the conditions for the formation of the rotating magnetic field, it is necessary to try to make the motor generate a rotating magnetic field, so the motor must have two-phase windings, one phase is the main winding (working winding), and the other phase is the auxiliary winding (starting winding). Applying different phase currents to the two windings produces a rotating magnetic field. In order to generate different phase currents, it is realized by connecting AC capacitors in series in the secondary winding, as shown in Figure 1.

(Figure 1 Schematic diagram of single-phase capacitor run asynchronous motor)

The application of AC capacitors is crucial in air conditioning systems, as they play a vital role in the starting and running of compressors and motors. The role of the AC capacitor is to make the secondary winding loop impedance capacitive, so that the current of the secondary winding leads the power supply voltage.

Because the main winding is inductive, its current lags behind the power supply voltage, so the secondary winding current leads the main winding current by a 90° phase difference, that is, a phase-separated induction current is generated, and a rotating magnetic field is generated to start and keep the motor running.

The AC capacitor connected in series is the starting and running capacitor of the motor. From the above analysis, it can be seen that this capacitor is essential for the starting and running of the compressor and the motor, and plays an important role in the starting and running of the compressor and the fan.

(Figure 2)

(Figure 2)

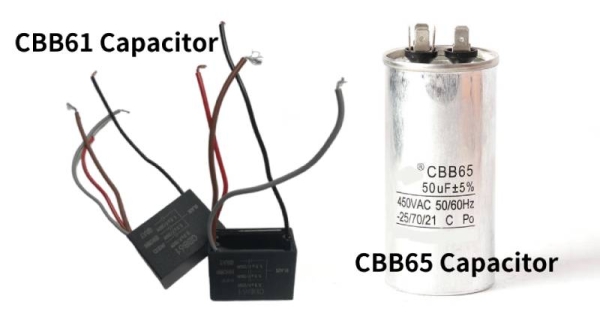

3 Introduction to CBB61 and CBB65 AC capacitors

The application of AC capacitor is evident in the specific types used in air conditioning systems. Air conditioner fan motors generally use CBB61 metallized polypropylene film AC motor capacitors (Figure 2 left); compressors generally use CBB65 metallized polypropylene film AC motor capacitors (Figure 2 right). This kind of capacitor is a non-polar capacitor with a negative temperature coefficient (that is, its capacity becomes smaller when the temperature rises) made of polypropylene film as the medium.

Advantages of metallized polypropylene film capacitors: wide capacity range, high insulation resistance, extremely wide operating voltage range, and wide operating temperature range. Can be metallized and has self-healing properties. Especially suitable for high frequency, high voltage, high stability, high pulse and AC occasions.

The capacity of CBB61 type fan capacitor is relatively small, and it is usually encapsulated into a sealed type with epoxy resin, a square plastic shell, the two electrodes are generally inserts (187 or 250), and welding leads are used as lead-outs.

The CBB65 type compressor capacitor has a relatively large capacity and is mainly used for starting and running a single-phase compressor. Its shape is generally designed as a cylinder, packaged with a metal shell, and filled with insulating oil inside for heat dissipation and sealing (anti-metal coating oxidation) , is a sealed structure. The two electrodes are generally welded by wires and 250 inserts are used as the lead-out ends. In addition, because of its large capacity, CBB65 series capacitors have an explosion-proof structure for safety reasons.

4 Safety and reliability requirements for AC capacitors used in air conditioners

The application of AC capacitor, such as CBB61 capacitor and CBB65 capacitor, is crucial in ensuring compliance with air conditioner safety standards.CBB61 and CBB65 AC capacitors are one of the key components of the air conditioner safety standards, and must meet the following requirements: (1) In the normal heating test, the surface temperature is required not to exceed the upper limit of the capacitor’s operating temperature, generally 70 ℃ . (2) In the abnormal test, capacitor opening and short circuit tests are required for compressor and fan capacitors, and the surface temperature during the test cannot exceed 150°C. (3) When the compressor and motor are at 1.1 times the rated voltage and rated frequency, the voltage across the capacitor during the start-up and operation of each gear should not exceed 1.1 times the rated voltage of the capacitor. (4) In terms of explosion-proof level, the new version of electrical safety standards has required that the application of fan capacitors must meet one or more of the following conditions:

——A capacitor with explosion-proof grade of P2/S2 or above is used;

——The capacitor is covered by a metal or ceramic case;

——The distance from the outer surface of the capacitor to the adjacent non-metallic parts should exceed 50mm;

——Adjacent non-metallic parts 50mm away from the outer surface of the capacitor can pass the needle flame test;

——Adjacent non-metallic parts 50mm away from the outer surface of the capacitor are at least V-1 level;

The above requirements mainly focus on the surface temperature and voltage of the capacitor, and the last one mainly examines the safety requirements of the capacitor and whether it is explosion-proof. The working temperature and voltage of the capacitor directly affect the service life and reliability of the capacitor. For the outdoor unit of the split type air conditioner, the capacitor is installed outdoors, and the operating environment is very harsh, with high temperature and high humidity in summer and low temperature and high humidity in winter, and is exposed to wind and sun all year round. Especially in the hot summer, the full-load running time of the air conditioner increases, and the running time of the compressor and the fan capacitor at high temperature also increases accordingly. Therefore, it is one of the important measures to improve the quality and safety of the air conditioner to select a capacitor that can maintain excellent electrical performance for a long time in a harsh environment, and will not explode or cause danger when it fails.

Conclusion

In conclusion, the application of AC capacitor in air conditioning systems is crucial for their proper functioning. AC capacitors serve as starting and running capacitors for compressor motors and fan motors, playing a vital role in initiating and maintaining motor operation. Capacitor selection should prioritize reliability, safety, and explosion-proof requirements to ensure optimal performance in the harsh environments faced by air conditioning units. By considering the specific application of AC capacitors in air conditioning, the overall quality and safety of these systems can be significantly improved.