The difference between electrode capacitor and electrodeless capacitor are the same in principle, both store charge and release charge. The difference lies in different media, different performances, different capacities, different structures, and different use environments and uses.

- Different media

Most polar capacitors use electrolyte as the dielectric material. Generally, capacitors of the same volume have large polar capacitance. In addition, different electrolytic materials and processes produce polar capacitors with the same volume capacity. Furthermore, the pressure resistance is also closely related to the use of dielectric materials. There are also many non-polar capacitor dielectric materials, most of which use metal oxide film and polyester. Because the reversible or irreversible performance of the medium determines the use environment of polar and non-polar capacitors.

- Different performance

Performance is the requirement for use, and maximum demand is the requirement for use. If the metal oxide film capacitor is used for filtering in the power supply part of the TV set, the capacitor capacity and withstand voltage required for filtering must be achieved. I am afraid that only a power supply can be installed in the case. Therefore, only polar capacitors can be used for filtering, and polar capacitors are irreversible. That is to say, the positive electrode must be connected to the high potential end, and the negative electrode must be connected to the low potential end. Generally, the electrolytic capacitor is above 1 microfarad for coupling, decoupling, power supply filtering, etc. Non-polarized capacitors are mostly below 1 microfarad, participating in resonance, coupling, frequency selection, current limiting, etc. Of course, there are also large-capacity and high-pressure-resistant ones, which are mostly used for the purpose of reactive power compensation of electric power, phase shifting of motor, and frequency conversion power supply.

- Different structure

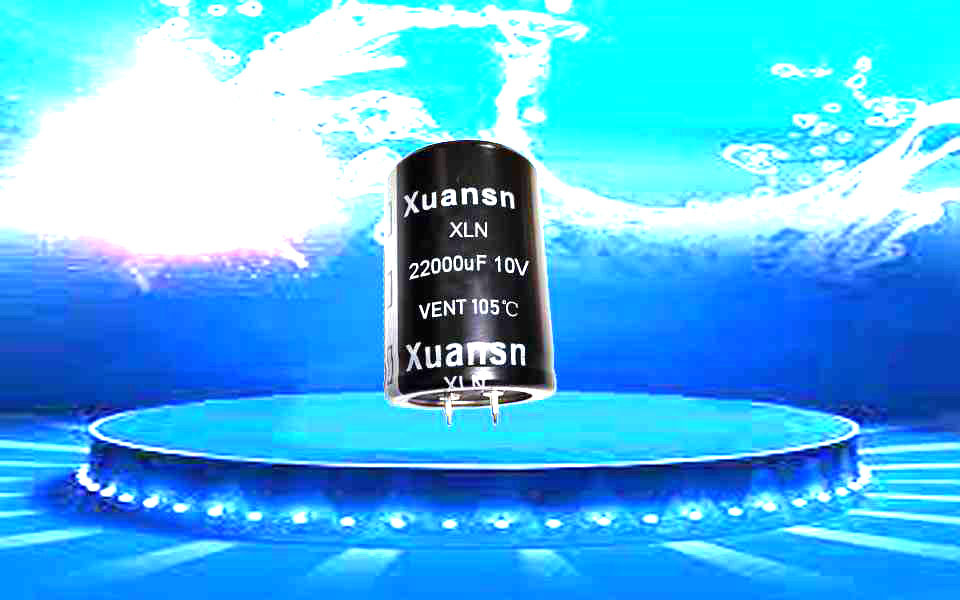

In principle, without considering the tip discharge, any shape of capacitors can be used in the environment. The electrolytic capacitors (polar capacitors) that are usually used are round, and the square ones are rarely used. The shape of non-polar capacitors varies. Like tube type, deformed rectangle, sheet type, square type, round type, combined square type and round type, etc., see where it is used. Of course, there are intangibles, which refers to distributed capacitance. The distributed capacitance must not be ignored in high-frequency and intermediate-frequency devices.

- Use environment and purpose

Because of the relationship between its internal materials and structure, the capacity of polar capacitors (such as aluminum electrolysis) can be very large, but its high frequency characteristics are not good, so it is suitable for power supply filtering and other occasions, but there are also good high frequency characteristics. Polar capacitor-tantalum electrolysis, its price is relatively high;Non-polarized capacitors are small in size, low in price, and good in high frequency characteristics, but they are not suitable for large capacity. Like ceramic capacitors, monolithic capacitors, and polyethylene (CBB) capacitors, ceramic capacitors are generally used in high-frequency filtering and oscillation circuits.Magnetic capacitor is a capacitor that uses ceramic material as a meson and burns a silver layer on the surface as an electrode. The performance of the magnetic dielectric capacitor is stable. Loss and leakage are very small, suitable for high frequency and high voltage circuit applications.Generally speaking, the insulating material between the two poles of the capacitor with a large dielectric constant (such as ferroelectric ceramics, electrolyte) is suitable for making large-capacity and small-volume capacitors, but the loss is also large. The small dielectric constant (such as ceramic) has low loss and is suitable for high-frequency applications.