In electronic components, we often consider some products. Is it better to choose a patch or a plug-in electrolytic capacitor? How to choose? How to choose electronic components that are more suitable for us according to the development of the market? Let’s talk about the fundamental difference between chip electrolytic capacitors and plug-in electrolytic capacitors. What information can we get from their fundamental differences.

The fundamental difference between SMD electrolytic capacitors and plug-in electrolytic capacitor is the installation method

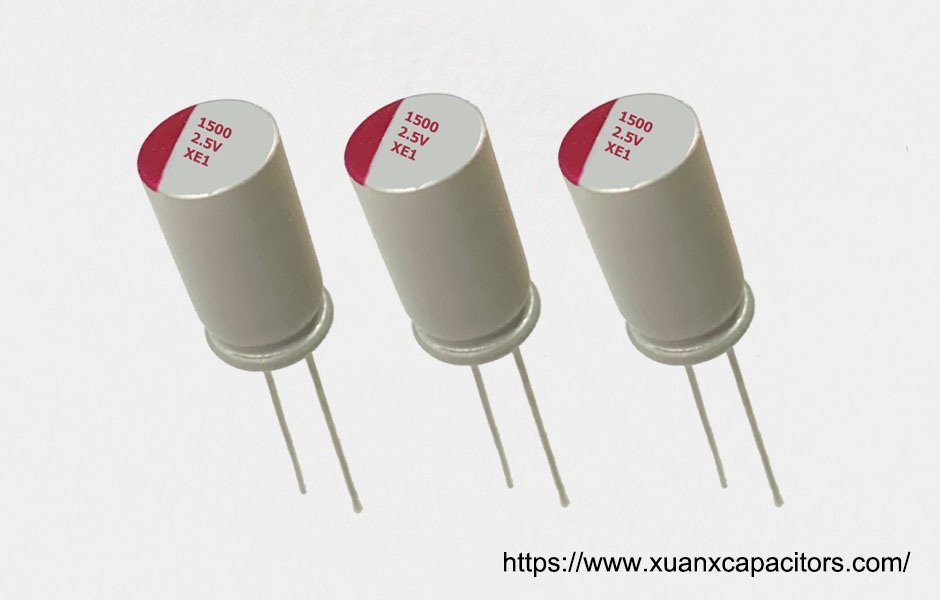

1. Whether it is the installation process of plug-in electrolytic capacitors or SMD electrolytic capacitors, the electrolytic capacitor itself is upright on the PCB board. The fundamental difference is that SMT (Surface Mount Technology, commonly known as SMD Process) installed capacitors have a black rubber base at the bottom. Why do SMD electrolytic capacitors need to install a rubber base? Because of this, the combination of surface soldered capacitor pins and PCB will be more stable. In addition, it can be understood from the literal meaning of SMT that the solder joints for surface soldering are on the front of the PCB, and the pins will not penetrate the PCB, while the pins of the plug-in electrolytic capacitor must penetrate the PCB, and the solder joints are on the back of the PCB.

2. SMD electrolytic capacitors can also be converted into in-line electrolytic capacitors, because many DIY players like to modify the motherboard or graphics card by themselves. In-line electrolytic capacitors can be soldered by hand with an electric soldering iron, while SMD electrolytic capacitors can only use expensive stickers. Chip machine for welding. Remove the patch to become a direct plug-in.

3. This principle also applies to factories. In order to increase production capacity, large and powerful factories will inevitably purchase multiple SMT placement machines to expand their production lines, so their graphics cards mostly use patch capacitors for automatic installation. However, ordinary small factories cannot afford to purchase placement machines or the number of placement machines is limited. They are only used to install the necessary small resistance and small capacitors, so the electrolytic capacitors are mostly in-line.

4. In addition, compared with countries with a small population, the cost of machinery will be relatively lower than the cost of labor, and the cost of labor will be relatively more expensive, so most of them will tend to manufacture SMT electrolytic capacitors. For China, a populous country, labor costs are lower than mechanical costs, so more manufacturers are more willing to use plug-in installations. Of course, the plug-in type is mostly used for low-end graphics cards, high-end graphics cards will try to avoid manual welding in order to ensure the quality.

The advantage of plug-in electrolytic capacitors is that they have low requirements for equipment and low labor costs, while the advantages of chip electrolytic capacitors are fully automated assembly line operation, high productivity and high precision, and chip electrolytic capacitors will not be like plug-in electrolysis during transportation. The capacitor is so easily damaged.